Programmer Sean Svajcsik enters a down-time reason code into eNET.

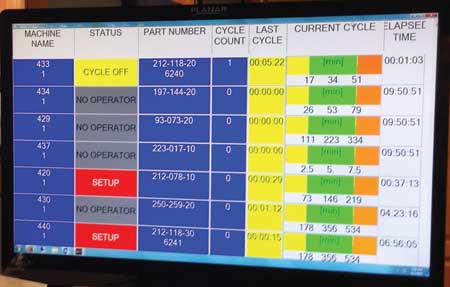

Real-time eNET monitoring dashboard

What started out as a 5S tool-room project to bring organization and reduce set-up times has blossomed into a full organization-wide commitment to getting lean for GEM Manufacturing Inc. The company offers contract prototyping, machining, finishing and assembly for some of the world's largest agriculture, oil and gas and hydraulic OEMs such as CNH, Eaton, Parker Hannifin, GE and Deere Corp. Started by brothers Rob and Kevin Gottschalk in June 2006 in Bristol, WI, GEM manufactures some 2,000 different parts annually with runs ranging from five to 50,000 pieces. By May 2011 they opened a second facility in Kenosha, WI, to be able to keep pace with customer demand.

Their first successful 5S tool room project inspired Kevin and Rob to proceed into a Quality Lab 5S project, and then a Kaizan event. That Kaizan event led to GEM's investment in January 2010 in an eNETDNC system for their shop to address inefficiencies with CNC program transfers and file rev control. "eNET's file rev control tools, like the Smart File Compare feature for edited-uploaded programs, insure that GEM's master programs will never be lost or even edited without management approval," said an eNETDNC spokesperson. Utilizing eNET also allowed operators to call and send programs quickly right from the machine control.

Previously, GEM relied on a time-consuming process of having to remotely cue programs from a CAM system, which involved the operators having to leave their machines to cue programs up from a workstation computer. This cumbersome process came to a head when the CAM systems were unable to transfer programs to GEM's new Mazak, Makino and Haas machine tools. "The eNETDNC system worked flawlessly for all of their machines and control types," said the spokesperson.

Encouraged by the fact that these lean tools were allowing GEM to improve costs, quality and delivery times for its customers, GEM appointed an in-house Coordinator of Continuous Improvement in 2011. Its organizational commitment to being Good Manufacturing Practice (GMP) compliant and applying lean and Six Sigma techniques throughout led directly to GEM Mfg. winning a Small Business of the Year award from KABA in November 2011.

Motivated to keep the lean momentum going, the Gottschalk brothers attended IMTS 2012 to learn about eNET's real-time machine monitoring. GEM was interested in streamlining the data captured on the floor and gaining insights into their machine utilization, so early 2014 they added eNET's Machine Monitoring & Data Collection.

According to Owner Rob Gottschalk, "We found eNET to be extremely customer-focused and since their hardware is made in the USA, the system is rock-solid, so they do not have to charge their customers yearly maintenance fees. They also provide free software and hardware updates and phone support, so choosing eNET for machine monitoring and data collection at GEM Mfg. was a no-brainer for us."

Fast-forward to today and Rob and Kevin are still satisfied with eNET for their machine monitoring. GEM Mfg. has even rolled out an employee incentive program tied to machine cycle-on %/chip cutting time, based on the real-world data they collect through eNET.

GEM Mfg. is ISO 9001:2008 certified and has over 50 machines between its two locations.

For more information contact:

GEM Manufacturing Inc.

19708 84th Place / P.O. Box 247

Bristol, WI 53104

262-857-7274

sales@gem-mfg.com

www.gem-mfg.com

eNETDNC

4702 S. 47th St.

Greenfield, WI 53220

414-817-7070

www.enetdnc.com