Alexander Hitzinger, Technical Director of the Porsche team. Mission accomplished: Porsche has achieved its 17th overall Le Mans victory at the 83rd running of the famous 24-hour race with a one-two finish.

After a break of 16 years, Porsche has now successfully continued its long tradition in motor sports with its return to the LMP1 class of the World Endurance Championship. In 2014, under the motto 'Mission 2014 - Our Return,' Porsche returned to the LMP1 class of the FIA World Endurance Championship after an absence of 16 years and made a strong performance with one win, six podiums and four pole positions in its first year. In 2015 the mission was accomplished. Porsche has achieved its 17th overall Le Mans victory at the 83rd running of the famous 24-hour race with a one-two finish. The drivers team for car number 19 won the coveted trophy in their innovative Porsche 919 Hybrid exactly 45 years after Porsche's first overall win at La Sarthe was achieved. The sister car number 17 added the icing on the cake, when they came in second.

Alexander Hitzinger, Head of LMP1 Development at Porsche, talks about the challenges Porsche faced on its return to the FIA World Endurance Championship (WEC) and the close cooperation with its technology partner, DMG MORI.

Mr. Hitzinger, what were the reasons that led Porsche to return to the LMP1 after such a long break?

A. Hitzinger: Motor sports and the brand Porsche have always been very closely linked, so we see this theme as a flagship of the company in the future as well. There are several reasons for our return to the LMP1 class: this is top-level motor sports and Porsche has a very successful history where endurance racing is concerned. We have also always kept close ties with the series and the regulations offer great possibilities for demonstrating technological innovations such as hybrid technology, as an example.

Motor sports has developed greatly over the last few years from the point of view of organization and technology. What were the biggest challenges you faced in this project and in the development of the Porsche 919 Hybrid?

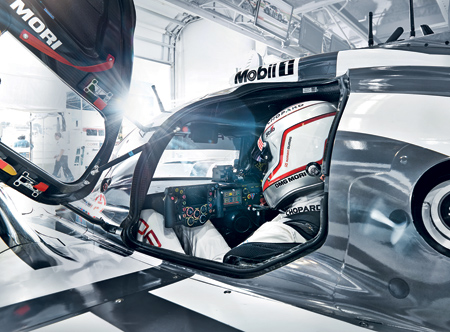

A. Hitzinger: The standards in the LMP1 class and the Le Mans prototype field have risen considerably in the last ten years. The greatest challenge for our return after more than a decade and a half was to build up an adequate organizational structure again. In the Development Department our personnel has expanded very quickly, from ten to begin with to now 150 employees. We started from scratch with the development of the Porsche 919 Hybrid, because we had no basic vehicle and therefore no references to build on.

What experiences have you had in this first season on the racetrack with regard to the development of the vehicle?

A. Hitzinger: We improved continuously from one race to the next in the last season and within a very short time were able to start with an extremely competitive vehicle. In the qualifying rounds Porsche has meanwhile evolved as a standard of its own. We have a steep learning curve to thank for this growing success, because continuous optimization of the vehicle and processes is vital in motor sports. The performance of the team deserves special mention here, because we saw most of the racetracks for the first time in the year 2014 and in this case had no experience to fall back on. So we learned a lot on every race weekend as well as in every test and put this new knowledge to good use very quickly, both on the racetrack and in development.

A one-two finish in what is only our second year is an amazing reward for the courage of our engineers regarding the 919 Hybrid's concept, and the relentless efforts of our 230 team members. I have to thank this brilliant team that has been growing together over the last three and a half years. We knew we were a lot better prepared than last year, but no way could we expect this result. We did not benefit from any situation, but we were on a winning level in every regard - be it the mechanics in the garage or the engineers doing the strategy.

You rely on the expertise of various suppliers in production. What criteria do you use to select these partners?

A. Hitzinger: Absolute quality is our top priority, although the expertise of a company in motor sports is also decisive. Because this is a guarantee that a supplier operates at the required high-level of technology and can meet the short delivery times reliably. Costs also play a decisive role, because we have to stay within budget targets.

Before the season 2014 started you presented DMG MORI as a premium partner of the Porsche LMP1 racing team. What distinguishes this cooperation?

A. Hitzinger: DMG MORI and Porsche are both technologically very innovative. This makes the companies a perfect match and is the basic condition for such a partnership. In addition, many of our suppliers use DMG MORI machines. This in itself speaks in favor of the quality and precision of the machines as well as a high level of experience with motor sports components. We wish to exploit this know-how within the cooperation and to develop new and efficient manufacturing solutions for our sophisticated components. Such innovations are vital for success, especially where motor sports are concerned.

And will you then produce these components yourself?

A. Hitzinger: Production will take place at DECKEL MAHO Seebach. DMG MORI has set up a department there dedicated solely to our applications. As we work so closely together we see this more or less as our own production. We ourselves use CNC technology from DMG MORI in Weissach for development work and prototype construction.

What do you expect from the cooperation with DMG MORI for the future and what are the aims with regard to motor sports?

A. Hitzinger: Further optimization of our processes and the Porsche 919 Hybrid are in focus. By working closely with DMG MORI on our manufacturing techniques, we hope to cultivate a technological and efficient edge that ultimately transfers to the racetrack. That is where we can continue the positive trend from last year - to secure as many podium finishes as possible.

Porsche Research and Development Centre in Weissach

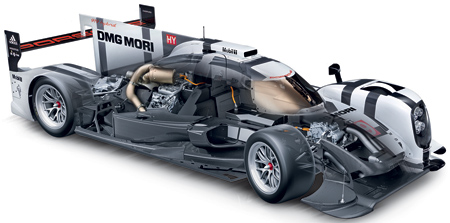

The development is marked by its speed - less than two years between the decision to return to the top class of the Sports Car World Championship 2011 and the first appearance of the Porsche 919 Hybrid on the company's own test track on June 12, 2013. In this time the Porsche Research and Development Centre in Weissach was extended to include a new office building and an LMP1 workshop for the Le Mans prototype. The team grew from zero to 230 racing experts, around 150 of whom are engineers. Machines, materials and components were procured - from high-voltage technology to a driving simulator. The most complex racing car Porsche has ever built was produced in record time. The car is the prototype for the future sustainable drive systems of the racing car manufacturer. The new efficiency regulations of the World Endurance Championship, which require a specific amount of energy per lap, were the decisive technological challenges that sparked Porsche's return. The in-house development and realization were the logical consequence. At the head of the Porsche team Enzinger (Head of LMP1), Alexander Hitzinger is Technical Director and the Team Manager is Andreas Seidl.

DMG MORI and Porsche

"Since 2014 DMG MORI has been the Premium Partner of the Porsche team in the FIA World Endurance Championship (WEC). The partnership between DMG MORI and Porsche is based on common attributes such as tradition, precision and technological leadership with a global presence," said a DMG MORI spokesperson.

"In DMG MORI, the racing team has found a partner, which as an innovation leader in the field of machine tool manufacturing can contribute to its success in motor sport. DMG MORI supports Porsche in two ways: First, as a long-time supplier for companies that make high-quality vehicle components for the team. Second, in the course of the current season a dedicated component production department has been set up at DECKEL MAHO Seebach that supplies Porsche with a growing range of vehicle components. The specially installed 'Porsche Motorsport CNC Competence Center' stands for precision, flexibility and the transfer of innovative technologies. The ultimate aim is to develop intelligent manufacturing solutions for demanding parts. Whereby the focus is explicitly on the long-term transfer of technology as the key cornerstone of sustainable success," said the spokesperson.

For more information contact:

DMG MORI USA

info@dmgmori.com

www.dmgmori.com

www.porsche.com/germany/sportandevents/motorsport