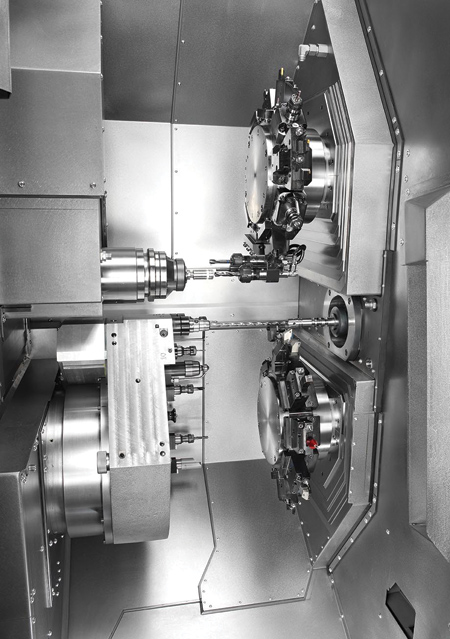

The TRAUB TNL32-11 is a sliding/fixed turning machine with two turrets and a front working attachment traversing in three axes. Three tools can be used simultaneously and independently of each other.

The signature feature of the TRAUB TNL32-11 is the front working attachment equipped with eight tool stations, four of which are live.

Up to three tools can be used simultaneously to produce independent contours.

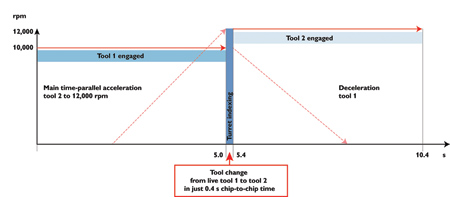

A highlight is the dual drive, consisting of two drives integrated within one turret. "This patented drive solution reduces non-machining time and thus also machining times per piece," said a company spokesperson.

The TRAUB TX8i-s controller features details such as reduced set-up time due to higher NC performance or the option of interactive programming, optimization and simulation in dialog or NC mode.

The TRAUB TNL32-11 is the latest addition to the TRAUB TNL32 sliding/fixed headstock automatic lathe series. Its signature feature is a front working attachment mounted on a cross-slide, which raises the number of linear axes on the machine to 11. This means that the TRAUB TNL32-11 can perform simultaneous machining with three fully independent tools. This saves machining time-especially for components with a high proportion of drilling.

The TNL32-11 has a headstock moving in the Z-axis, an upper and identical lower turret with X, Y and Z-axes, and a counter spindle movable in the X and Z directions. A new feature is the front working attachment, which sits on an additional cross-slide moving in the X and Z-axes. It provides the user with further, freely positionable tools and enables the use of up to three tools, simultaneously and independently of each other.

Interpolating Y-Axis

In addition to the two linear X and Z-axes, the front working attachment features a CNC circular axis. By the interpolation of the rotary axis with the X-axis and the C-axis of the main spindle, the front working attachment can also be used in the Y direction using an interpolated Y-axis. The particular benefit: when a drilling tool needs to be corrected to exact center, the necessary corrections can be performed via the CNC controller. This can be of help with small parts that react with great sensitivity to even minimal offset errors.

The large clearance circle of the tool mountings of the front working attachment was chosen deliberately: its generous size allows simultaneous and collision-free machining together with the two tool turrets on the main spindle.

Eight Additional Tools Plus One Gripper Station

The front working attachment makes eight additional tool stations available. Four of them are used to mount fixed tools; the other four are for live tools.

There is also a station for a workpiece gripper that can unload a machined workpiece from the counter spindle. A time-saving advantage: while the finished workpiece is discharged from the counter spindle, the next part can already be machined with two tools at the main spindle.

With an output of up to 3.4 kW and a maximum speed of 12,000 revolutions, the tool drive in the front working attachment is productive and designed for high power. The toolholders are designed to be highly robust and stiff with a mounting shank diameter of 36 mm. Individually controllable coolant pressure of up to 80 bar is available at every station. One live station can be used as a deep-hole drilling station with a coolant supply up to 120 bar. The front working attachment can also be used as a tailstock when producing long components.

Large Work Area

The work area is easily accessible to the operator due to its high and wide sliding door, simplifying set-up and changeovers. A large inspection window allows the operator to keep a close eye on the machining process. "The long Z travel of the headstock means the machine can easily be used for sliding or fixed headstock turning without compromises," said a company spokesperson. "The conversion effort is less than 15 minutes."

Two Drives in One Turret

Indexing is performed using an NC rotary axis that controls movement via an internally meshing planetary gear. This allows the turret to be indexed to any preferred position without a mechanical locking mechanism being necessary. The free positioning of the turret makes multiple tool assignment possible on each station.

Another highlight is the dual drive, consisting of two drive trains integrated within one turret. "This patented drive solution reduces non-machining time and thus also machining times per piece," said the spokesperson. "While one tool is in use, the tool intended for the next work step can be accelerated up to the desired speed during main time and is immediately available at full speed after the turret indexing operation. Jerky accelerations and delays that were previously unavoidable when reducing auxiliary processing times are now a thing of the past. In addition, the user benefits specifically from the fact that toolholder wear is reduced due to the lower acceleration values. Even with live tools, chip-to-chip times are around just 0.3 seconds."

Improved Tool Mountings

The TRAUB compact shank system is used in the turrets, enabling precise mounting of toolholders. "They are seated deeper in the turret than in other commercial systems, which results in less leverage effect and thus greater stiffness," said the spokesperson. "For live toolholders, the large 45 mm shank diameter allows for the installation of spindle bearings with large diameters. A quick-change system enables high-precision, smooth exchange of tools without removing the toolholder. The compact shank system verifiably increases the tool life and also contributes to improved surface quality."

Low Space Requirements

The machines in the TNL32 series are compact, aided by the control cabinet integrated in the upper area of the machine. For servicing, only a few manipulations are needed to remove the back cover to allow full access to the mechanical assemblies. The hydraulic and pneumatic components are also arranged with full accessibility to the rear of the machine and can be easily checked at a glance.

Control Family

The TNL32 series is equipped with the TRAUB TX8i-s control and the TX8i-p for the TNL32-9P. Both models are based on CNC hardware from Mitsubishi, while the controllers' user interface software is a TRAUB development.

"Customers need not rely on standardized software products; rather customer and application needs can be implemented and integrated optimally into the development," said the spokesperson. Both controllers are compatible with all previous TRAUB controllers so that existing programs can be used.

The spokesperson noted the following TRAUB controller features and benefits:

- Reduced set-up time due to higher NC performance

- Interactive programming, optimization and simulation in dialog or in NC mode

- Error avoidance and set-up time reduction through object-oriented interactive guidance

- Sensitive tool breakage and wear monitoring

- High availability

- Optimal support because the machine, control and drive are from a single source.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

www.indextraub.com

Southwest

N. TX

Hillary Machinery, Inc.

1825 Summit, #207

Plano, TX 75074

972-578-1515

www.hillaryinc.com

S. TX

PD Browne South

440 Brenmar

Houston, TX 77060

281-405-9378

www.pdbrownesouth.com

OK

Gage Machine Tool

10668 Widmer Road

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

Southeast

AL, GA

Applied Machine Solutions, Inc.

2200 Airport Industrial Dr., Suite 300

Ball Ground, GA 30107

678-880-0893

info@appliedmachine.com

www.appliedmachine.com

NC, SC, VA

Advance Machinery Sales, Inc.

416-C Gallimore Dairy Rd.

Greensboro, NC 27409

336-665-9114

www.am-sales.com

FL

Arthur Machinery

5903 Johns Rd

Tampa, FL 33634

813-887-4455

www.arthurmachinery.com

Northeast

DE, MD, E. PA, NJ, NYC, Long Island

Automation Solutions, Inc.

2 Hagerty Blvd., Ste. 300

West Chester, PA 19382

610-430-3670

inquire@asi-pa.com

www.asi-pa.com

N. NY

Britton Machinery Sales

P.O. Box 709

Pittsford, NY 14534

585-924-9335

www.brittonmachinery.com

W. PA

Marcus Machinery

106 Bellefield Court

Gibsonia, PA 15044

412-862-0803

info@marcusmachinery.com

www.marcusmachinery.com

MA, CT, RI, ME, NH, VT

Northeast CNC, LLC

36 Bartlett Rd., Unit 1

Gorham, ME 04038

207-775-5510

sales@necnc.com

www.necnc.com

Midwest

KS, W. MO

Gage Machine Tool

10668 Widmer Rd.

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

E. WI

Iverson & Company

441 North 3rd Ave.

Des Plaines, IL 60016

847-299-2461

sales@iversonandco.com

www.iversonandco.com

MI

Methods & Equipment Associates

31731 Glendale Ave.

Livonia, MI 48150

734-293-0660

sales@methods-equipment.com

www.methods-equipment.com

MN, IA, ND, SD, E. NE, W. WI

Hales Machine Tool, Inc.

2730 Niagara Lane North

Plymouth, MN 55447

763-553-1711

sales@halesmachinetool.com

www.halesmachinetool.com

West

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street E.

Fife, WA 98424

253-926-6868

sales@ellismachinery.com

www.ellismachinery.com