ShaftGrind with Multiwheel Transmission Shaft Technology

Highly productive grinding of gearshafts in one single plunge

Throughfeed grinding of planetary gear pins on a KRONOS L

Multiple production for high productivity

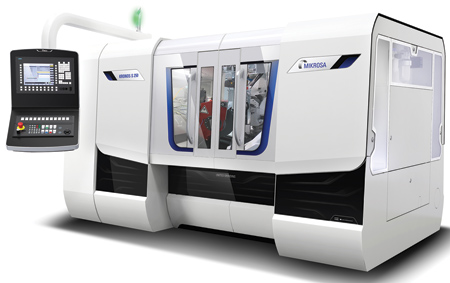

Centerless cylindrical grinding machine KRONOS S 250

As part of its recent Motion Meeting 2016 in Thun, Switzerland, United Grinding presented its latest technologies for automotive transmission applications. A transmission is essential for all cars with a combustion engine. The gear converter is connected directly downstream of the engine and converts speeds and torques along the power train. "The aim is to make the engine as efficient as possible, with the highest possible driving dynamics," said a company spokesperson. "Whether manual transmission, automatic transmission or dual clutch transmission - all contain countless precision parts that can be machined on machines from Schaudt Mikrosa GmbH."

SCHAUDT MIKROSA offers efficient machining solutions for many applications in the field of transmissions. The SCHAUDT ShaftGrind series, which is based on the camshaft grinding platform CamGrind, is designed for grinding input, output or intermediate shafts. For centerless grinding applications, all machine sizes in MIKROSA's KRONOS series are used. They can machine precision workpieces such as control spools for control units, planetary gear pins, shifter rods or needles for needle bearings with efficiency.

Grinding of Gear Shafts

"The conventional machining process for a gear shaft is difficult to standardize. Flexible solutions and new approaches are needed here," said the spokesperson. Different qualities of the bearing positions along a workpiece, divergent references for bearing positions and centers as well as the machining of bearing, keyway and spline diameters and shoulder surfaces place high demands on both machine and grinding process.

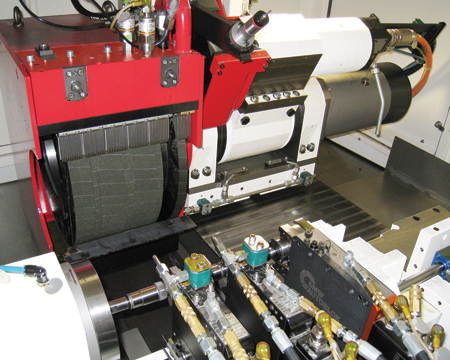

"SCHAUDT meets these challenges with the ShaftGrind series, which offers an individual combination of suitable machining and machine concepts for a variety of grinding tasks," said the spokesperson. From concepts with one grinding wheel to flexible solutions with up to four grinding wheels, various machine configurations are possible. "The result are efficient and relatively cost-effective solutions for transmission manufacturers," said the spokesperson.

The ShaftGrind S can be equipped with two grinding spindles, for example. The shaft diameters are ground with a ceramic-bound CBN grinding wheel on the main spindle, while the swivel-in spindle for machining the shoulders has a galvanic-bound CBN grinding wheel set. Due to integrated first contact detection the cycle time can be significantly reduced, as the machine detects fluctuations in the rough part stock allowance and only switches from rapid feed to grinding feed in the case of contact.

"Gear shafts can be machined even more effectively on the ShaftGrind L2," said the spokesperson. This machine is equipped with two cross slide systems with up to four grinding spindles (two main spindles and two swivel-in spindles), which can operate simultaneously. "This allows the grinding time for diameter machining to be almost halved," said the spokesperson. In-process measuring heads monitor the diameter dimensions to help ensure production reliability. Swivel-in spindles with galvanic-bound CBN grinding wheel sets are used for machining the keyways. "The machine can achieve a productive cycle time, together with high process reliability," said the spokesperson.

Multiwheel Transmission Shaft Technology

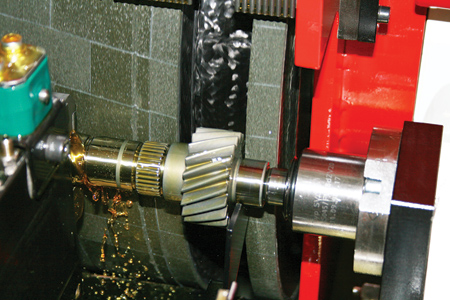

The Multiwheel Transmission Shaft Technology has been developed specifically for highly productive gear shaft applications. It allows synchronous machining of all bearing positions and spline diameters in a single plunge. A grinding tool with several wheels has been developed, which isolates spline machining from diameter machining in terms of vibrations. Machining times of just 15 seconds can be achieved. If plane surfaces and flat shoulders are also machined, the machines' wheelhead can be extended by a swivel-in spindle in accordance with the performance criteria. The concept is designed for maximizing productivity in gear shaft machining.

However, centerless machining can also be used for gear shafts. On machines of the KRONOS series all seats are ground in a single plunge, including machining of the spline gear. "In this case too, it is difficult to prevent the transmission of rounding errors from the gear to the diameters. A great deal of experience is needed for the configuration and setup of the grinding process," said the spokesperson. An advantage of centerless grinding is that the workpiece is supported along its lateral surface on the workpiece rest and on the regulating wheel, so that any deflection of the shaft can be prevented. This enables enhanced quality as well as a short grinding time.

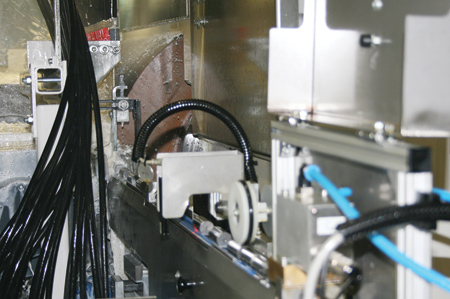

Centerless Machining for Precision Parts

"In addition to the various gear shafts there are many other precision workpieces in the transmission that are ideal for centerless machining," said the spokesperson. Planetary gear pins, which are found in large quantities and different sizes in every automatic transmission, and needles for needle bearings are suited for through grinding, for example. Needles with an allowance of 0.1 mm, a workpiece diameter of 5 and a length of 16 mm, can be ground on a KRONOS M 400 at a speed of up to 16 m per minute. This gives roughly 1,000 finished parts per minute. Dressing occurs continuously and in parallel with the grinding process. So while machining is underway on the front side of the grinding wheel, the rear side is dressed simultaneously. "In addition to high productivity, these workpieces also have extreme demands on surface quality. Impressive values of Rz 0.4 and 0.5 microns are achieved when machining planetary gear pins - and that is with grinding," said the spokesperson.

Other workpieces are ground using the plunging method in single or multiple production. Control spools, found in great variety in the control units of automatic and dual clutch transmissions, can be machined efficiently on a KRONOS S 250 in fourfold production, for example. Shifter rods for manual transmissions are ground on a KRONOS L 660 in double production. "This allows for a reduction of cycle times and a decrease of unit costs, despite higher investment costs. The machines are part of a complete machining line," said the spokesperson. The parts are fed into the machine via a handling system, machined and finally measured and palletized.

For more information contact:

UNITED GRINDING North America, Inc.

510 Earl Blvd.

Miamisburg, OH 45342

937-859-1975

info@grinding.com

www.grinding.com

Southwest

E. TX

Charles Harter

CJ Harter & Son Machinery Inc.

550 Westcott, Suite 375

Houston, TX 77007

713-227-7221

harterhou@sbcglobal.nex

AR, LA

Steve Wherry

Cardinal Machinery

7535 Appling Center Dr.

Memphis, TN 38133

901-377-3107

s.wherry@cardinalmachinery.com

www.cardinalmachinery.com

NM

Mike Geoffroy

The Geoffroy Company, Inc.

5910 S. University Blvd, C-18 #211

Greenwood Village, CO 80121

303-756-3684

TGCIdenver@comcast.net

Southeast

AL, MS, TN, FL (Panhandle)

Steve Wherry

Cardinal Machinery

7535 Appling Center Dr.

Memphis, TN 38133

901-377-3107

s.wherry@cardinalmachinery.com

www.cardinalmachinery.com

VA, NC, SC, GA

David Chesnutt

Methods Machine Tools, Inc.

13607 South Point Boulevard

Charlotte, NC 28273

704-587-0507

dchesnutt@methodsmachine.com

www.methodsmachine.com

Northeast

NY (All Except NYC & Long Island)

Gordon Britton

Britton Machinery Sales, Inc.

330 Castlebar Rd.

Rochester, NY 14610

585-721-4160

gbritton@brittonmachinery.com

W. PA

Mark Henne

Marcus Machinery

106 Bellefield Court

Gibsonia, PA 15044

412-862-0803

mark.henne@marcusmachinery.com

www.marcusmachinery.com

WV

Chip Storie

Ellison Technologies

5333 Muhlhauser Rd.

Hamilton, OH 45011

513-874-2736

cstorie@ellisontechnologies.com

www.ellisontechnologies.com

DE, MD, NJ, E. PA, NY (NYC & Long Island)

Chris Cowan

Tuckahoe Trading

94 N. Hamilton St.

Doylestown, PA 18901

215-345-9275

chris@tuckahoetrading.com

www.tuckahoetrading.com

Midwest

MN, ND, SD, N. IA, W. WI

Dan Hales

Hales Machine Tool Inc.

2730 Niagara Lane North

Plymouth, MN 55447

763-553-1711

dhales@halesmachinetool.com

www.halesmachinetool.com

E. WI

Bob Stoltz

Merwin Stoltz Machine LLC

N30 W28979 Lakeside Road

Pewaukee, WI 53072

800-923-6255

merwinstoltzmachinellc@gmail.com

MO

David Smith

CJ Smith Machinery Company

2275 Cassens Dr., Suite 123

Fenton, MO 63026

636-349-7757

dsmith@cjsmith-machinery.com

www.cjsmith-machinery.com

IN, N. IL

Chris Tauber

Integrated Machinery Systems

101 North Prospect Ave.

Itasca, IL 60143

630-250-8305

chris.tauber@imscnc.com

www.imscnc.com

KY

John Stephenson

Tri-S

3 North Shaw Lane

Fort Thomas, KY 41075

859-380-5909

trisjohn@fuse.com

KY, OH

Chip Storie

Ellison Technologies

5333 Muhlhauser Rd.

Hamilton, OH 45011

513-874-2736

cstorie@ellisontechnologies.com

www.ellisontechnologies.com

MI

Brad Contrucci

Tooling Systems Sales

1782 Apple Ridge Court

Rochester Hills, MI 48306

248-656-2035

bradc@tssgrinding.com

www.toolingsystemssales.com

West

AZ

Richard Adams

Adams Machinery

215 S. Rockford Dr., Suite 101

Tempe, AZ 85281

480-968-3711

dick@adamsmachineryaz.com

www.adamsmachineryaz.com

S. CA

Jay Davis

DMARK Corporation

10552 Humbolt St.

Los Alamitos, CA 90720

562-799-9010

jdavis@dmarkcorp.com

www.dmarkcorp.com

NV, N. CA

John Franchuk

Die Mold Machinery

300F Danville Boulevard #323

Alamo, CA 94507

925-831-0920

john@diemoldmachinery.com

www.diemoldmachinery.com

CO, E. WY

Mike Geoffroy

The Geoffroy Company, Inc.

5910 S. University Blvd, C-18 #211

Greenwood Village, CO 80121

303-756-3684

TGCIdenver@comcast.net

MT, UT, S. ID, W. WY

James Grisley

JM Grisley Machine Tools, Inc.

1485 South 300 West St.

Salt Lake City, UT 84115

801-486-7519

sales@jmgrisley.com

www.jmgrisley.com

OR, WA, N. ID

Gary Anderegg

Machine Toolworks, Inc.

14600 Interurban Avenue South

Tukwila, WA 98168

206-575-3390

ganderegg@machinetoolworks.com

www.machinetoolworks.com