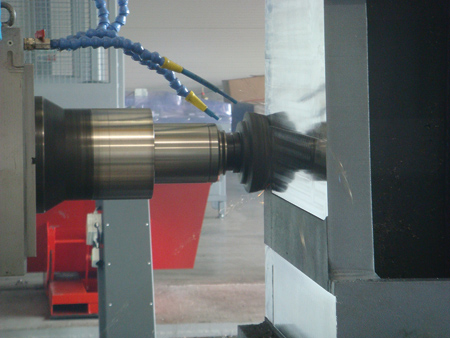

Stanislav Svoboda, Owner of Kovoobrabeni-Svoboda s.r.o., a job shop in the Czech Republic, with the new Fermat WFT 13R CNC table type horizontal boring mill (HBM). The large workpiece on the rotary table is a fixture that will be used on the machine for holding large complex workpieces. The heavy-duty 5" spindle (see inset) machines hardened metals with precision.

INSET in number 1 photo above

The robotic tool changer, with 105 tool storage capacity, quickly changes tools on the spindle of the WFT 13R CNC HBM. The position of the robotic tool changer allows for more space around the spindle for machining of large components.

Stanislav Svoboda, son of Stanislav Svoboda, is a machinist in the shop.

HBM Motocross poster

HBM Motocross Trophies

Stanislav Svoboda has won many trophies in motorcross in the Czech Republic and Europe. His friends and family created the poster on his 50th birthday to celebrate his motorcross accomplishments.

Stanislav Svoboda, Owner of Kovoobrabeni-Svoboda s.r.o., a job shop in the Czech Republic, determined he needed new technology to achieve larger machining capacity. Some of the machining jobs he was receiving requests for had to be outsourced.

The shop, founded in 1989, already had two small boring mills along with a variety of other machines but needed a boring mill with the capacity for large complex parts.

"We did not want an older, used machine because we wanted to be able to program it offline on a PC as well as on the CNC control," said Svoboda. "And we were looking for a machine that would be reliable for many years to come."

The job shop machines a wide range of components including specialty gears, large molds, machine tool parts, automotive parts and serves a variety of other industries.

A Fermat WFT 13R CNC table type horizontal boring mill (HBM) was chosen to provide the larger part capacity Svoboda required. "We considered Fermat as a reliable brand at a good price and the WFT 13R CNC HBM could produce larger components to meet our customer's requirements."

The Fermat WFT 13R CNC HBM purchased provides five linear axes: X (196.85"), Y (98.4"), Z, V and W and one rotary axis. The full servo rotary table option chosen provides continuous B-axis rotation for contouring simultaneously with the linear axis. During machining the column provides Z-axis movement and the workpiece is clamped on the rotary table that travels in the X-axis. The Y-axis ballscrew is 80 mm in diameter.

Three different CNC rotary table options are available:

- 1,600 mm by 1,800 mm,

- 1,800 mm by 2,200 mm with a maximum table load of 15 metric tons,

- 1,800 mm by 2,600 mm with a maximum table load of 20 metric tons,

- 2,000 mm by 2,400 mm with a maximum table load of 20 metric tons,

- 2,500 mm x 2,500 mm with a maximum table load of 20 metric tons,

- 2,000 mm by 3,000 mm with a maximum table load of 20 metric tons.

Svoboda chose one of the largest table options with the 20 metric ton capacity so the shop would not be limited in its machining capacity.

The Heidenhain iTNC 530 control was specified for this machine. The machine is also available with FANUC or Siemens controls. At Kovoobrabeni-Svoboda the programming is often performed offline on a PC using Solidworks. But when the component is simple to machine the programming can be done at the control. The Heidenhain control also handles in-process probing including measuring and cutting tool probing.

The option to add an automatic machining head was added for greatly increased flexibility. The automatic head resides in a pick-up station until it is required. Then the machine, utilizing the control, automatically loads the head and makes all of the connections required in preparation for machining.

"We chose to add the automatic head option because it provides machining at any angle for complex components," said Svoboda.

The shop also utilizes a smaller manual head on the HBM for machining in tight spaces.

Another option chosen for the WFT 13R CNC HBM is the traveling ram, hence the designation of the "R" in WFT 13R. The ram allows the machine to extend the spindle another 23" in addition to the normal 29" travel for more flexibility to machine all types of parts.

The robotic tool changer is another Fermat option chosen for the new HBM. The machine comes standard with an automatic double tool changer. The robotic tool changer, with 105 tool capacity, allows for more tools to be available to the machine and leaves the area around the machine free for the large components. A Kuka robot quickly moves the required tool to the spindle.

The first item to be machined on the Fermat WFT 13R CNC HBM was a large fixture designed to hold a large workpiece for machining on the new HBM. "One type of component to be machined is for gear boxes. We will be able to machine a complex part in one clamping on the new machine," said Svoboda.

Kovoobrabeni-Svoboda s.r.o. was started in Stanislav Svoboda's garage with one small lathe. The company has grown to employ 25 people including other family members. Svoboda's son, also named Stanislav, is a machinist in the shop. "We are now prepared to machine large, high quality, complex parts with our new Fermat WFT 13R CNC table type HBM," said Svoboda.

For more information contact:

Paul Mandelbaum

Lucas, A Fermat Group Company

13020 St. Clair Ave.

Cleveland, OH 44108-2033

216-451-5588

sales@lucasprecision.com

www.lucasprecision.com

Jan Ferenc

FERMAT Machinery

Prumyslova 11

102 19 Prague 10

Czech Republic

420-774-339-579

export@fermat-machinery.com

www.fermatmachinetool.com

Stanislav Svoboda

Kovoobrabeni-Svoboda s.r.o.

kovo_svoboda@volny.cz