New Production Monitoring Product

January 1, 2017

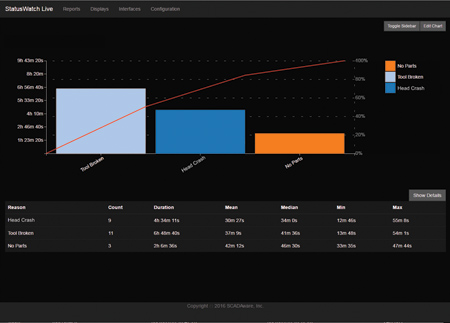

SCADAware simplified, Andon-based production monitoring system, StatusWatch Live

SCADAware, Inc., a leader in control system integration, has introduced its StatusWatch production intelligence and plant efficiency product line. SCADAware developed StatusWatch to monitor asset utilization and analyze plant efficiency. The Andon-based system consists of visual products and systems that interact to alert management, maintenance and operators of a quality or process problem within a facility. "StatusWatch products have consistently helped manufacturers achieve a 20% or more increase in Overall Equipment Effectiveness (OEE) by maximizing plant efficiency through real-time data collection, timely decision making, improved accountability and continuous improvement," said a company spokesperson.

"StatusWatch Live can bring implementation of the production intelligence products to a broader base of manufacturers," said the spokesperson. It is a standalone, user-friendly system that does not require the use of the customer's server. StatusWatch Live's primary focus is on live data relevant to the current situation on a shop floor. Current machine/Andon states, discrete part counts, current program number and other live data is collected and used by StatusWatch Live for notifications, display and reporting.

"This is a plug-and-play product designed for optimal user experience and ease-of-use," said Rick Caldwell, President of SCADAware.

The entire StatusWatch line includes:

- StatusLight Smart Andon - Cut response times with high-visibility StatusLight Smart Andons. Customize light behaviors to assign unique significances to user input from a button press, bar code scan or even a button press on another StatusLight. Configuration is made easy with a point-and-click interface. StatusLights integrate seamlessly with StatusWatch.

- StatusLight Call and Response System (CRS) Application - Quickly communicate needs with the StatusLight CRS. Send a request for anything from materials to maintenance directly from a StatusLight. Any responder can then view, respond to, and signal the request complete through the CRS application. StatusWatch users can collect this CRS data to gather an even deeper insight.

- StatusWatch Line Sign Application - Allows users to see more of their facility at a glance. The Line Sign displays the status of many machines or Andon devices in real time. View any number of screens in rotation and know instantly where help is needed.

- iStatusWatch iPad App - Find out exactly what is happening on the shop floor, right from an iPad. View the current status of all your StatusWatch connected devices on a single screen. Run reports specially catered to an iPad, even view multiple reports at once.

- StatusWatch PC Interface - Augment machine data with the StatusWatch PC Interface. Sometimes, a machine's raw state data does not show exactly what it means. Use the PCI to correct, adjust or add to the data coming from a station to gather more meaningful insight. Add comments, sign operators into a machine, signal part reworks and more.

For more information contact:

SCADAware Inc.

2023 Eagle Road

Normal, IL 61761

309-665-0135

info@SCADAware.com

www.StatusWatch.com

www.SCADAware.com

< back