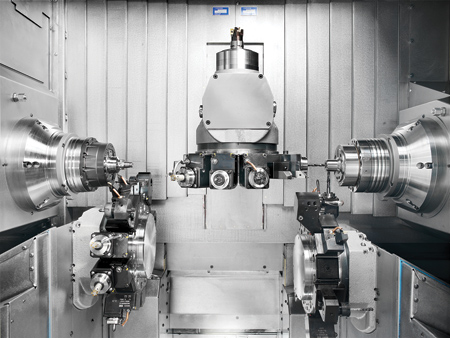

The vertically arranged machine bed and other smart design features result in a spacious work area, with 660 mm of turning length now available. A second lower turret makes the machine more productive.

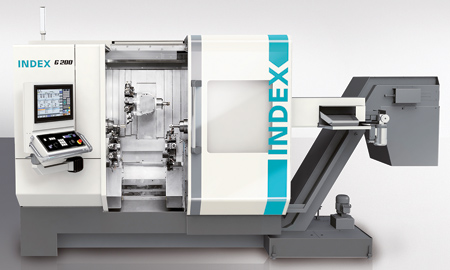

The redesigned G200, capable of complex part processing, can offer up to 30% greater productivity, depending on the workpiece.

INDEX has developed a new generation of its G200 turn-mill center. The new compact machine offers significantly higher performance - potentially up to 30% greater productivity - in the same footprint as the earlier generation. The machine redesign has increased the maximum turning length to 660 mm, and has resulted in a higher performance milling spindle, expanded live tool complement and an XPanel with i4.0 readiness. The new machine offers flexibility and high-speed machining of both bar stock and chucked parts complete in one set-up.

The machine bed is arranged vertically, making the machine stand higher, but extending in the work area, thus permitting the second lower tool carrier to increase machine productivity. "Reducing cycle times by 30% compared to the first G200 generation is well within the bounds of possibility with appropriate workpieces," said an INDEX spokesperson.

The fluid-cooled main and counter spindles are designed identically and feature a bar capacity of 65 mm (max. chuck diameter 165 mm). Motorized spindles allow productive turning machining with a power of 31.5/32 kW (100%/40% duty cycle), a torque of 125/170 Nm and a maximum speed of 6,000 RPM.

The G200 has three tool carriers so tools can be assigned to almost any machining type on the main and counter spindles independently. This means greater flexibility for the programmer in organizing the machining steps.

Due to the large work area, it is possible to work with three turrets simultaneously on the main spindle or counter spindle without them interfering with each other. One example: the lower right turret with an angular tool can machine the inside of a workpiece clamped in the main spindle, while the other lower turret and upper tool carrier machine the outside. The same is also possible on the counter spindle. This increases the possibility to use three cutting edges simultaneously, and in some cases even four tools.

The two 14-tool turrets are arranged in mirror image, each with an independent Y-axis (+/- 45 mm). All tool stations can be equipped with live tools. Tools with internal coolant supply (up to 80 bar) can be used as well.

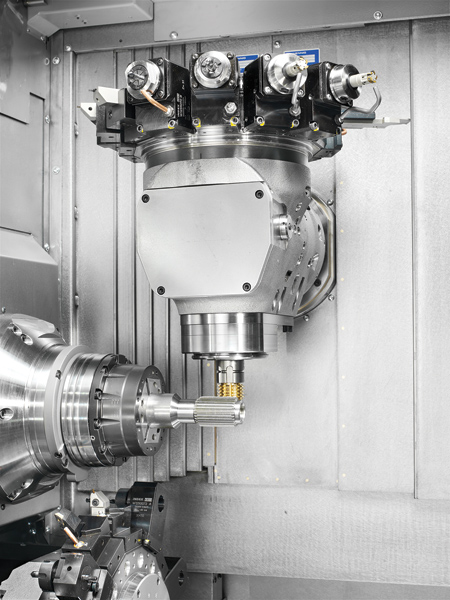

A special feature is the upper tool carrier, which has an additional Y-axis (+/- 65 mm) and a 360° swiveling B-axis. It is designed on one side to provide an added 14 tool positions and has a milling spindle on the rear. Its drive delivers speeds up to 7,200 RPM (power 22 kW, torque 52 Nm at 25% duty cycle). The upper turret head can be swung into a horizontal position about the B-axis and then moved into the work area up to a position of 30 mm below the spindle center. In this position, the turret can machine towards the main or counter spindle, or even simultaneously, depending on the application. This position is often used to perform face machining with straight tools.

A feature of the lower tool carriers is the parking positions. The turrets are designed to move to the left or right to a position that is outside of the work area, avoiding risk of collision. This allows the other tool carrier to work freely over the entire turning length. Also, the 845 mm slide travel of the upper tool carrier is dimensioned in the Z-axis so that the tool covers the complete turning length of 660 mm without having to rotate the B-axis by 180°.

The INDEX Xpanel i4.0 ready control concept of the new INDEX G200 generation focuses on productivity and ease of use. Numerous control elements of the machine operating panel have been integrated into the screen, where they can be operated directly on the 18.5" touchscreen with visual support. The remaining keys on the machine control panel are provided with LED backlighting for a better user dialog. The operating panel provides the option to display the control screen in a second view. Using this second page, Xpanel i4.0 ready can, for example, display the INDEX Virtual Machine (VM) simulation directly on the machine (optional).

The operator can quickly switch between the control screen and the On-board Virtual Machine and use the simulation either independently or coupled with the current machine operation. In Crash Stop Mode, if a virtual collision is detected, the running workpiece program is stopped before the actual crash, preventing any damage. In RealTime Mode, the machining process can be observed in real time simultaneously on the machine control panel.

Another new feature is the openness of Xpanel i4.0 for information technology (IT) extensions. The VPC box (industrial PC, optional) can be used also for any other type of customer application. With such a directly networked control, any information and application can be retrieved from the company and operated on the machine.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

www.indextraub.com

SOUTHWEST

N. TX

Prosper Machine Tools, LLC

7415 Whitehall Street, Suite 123

Richland Hills, TX 76118

682-626-5537

www.prospermt.com

S. TX

PD Browne South

440 Brenmar, Ste. 3150

Houston, TX 77060

281-405-9378

www.pdbrownesouth.com

NM

AME, Inc.

(Adv. Mfg. Eng., Inc.)

5770 Clarkson Street #C

Denver, CO 80216

303-922-9266

www.amerm.com

OK

Gage Machine Tool

10668 Widmer Road

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

SOUTHEAST

NC, SC, VA

Advance Machinery Sales, Inc.

416-C Gallimore Dairy Rd.

Greensboro, NC 27409

336-665-9114

www.am-sales.com

TN, AL, MS, FL (Panhandle)

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

901-377-3107

www.cardinalmachinery.com

FL (except Panhandle)

Arthur Machinery

5903 Johns Rd

Tampa, FL 33634

813-887-4455

sales@arthurmachinery.com

www.arthurmachinery.com

NORTHEAST

N. NY

Britton Machinery Sales

330 Castlebar Rd.

Rochester, NY 14610

585-924-9335

www.brittonmachinery.com

W. PA

Marcus Machinery

106 Bellefield Court

Gibsonia, PA 15044

412-862-0803

info@marcusmachinery.com

www.marcusmachinery.com

MA, CT, RI, ME, NH, VT

High Performance Machinery

313 South Main St.

Orange, MA 01364

978-204-6501

hpm@mass.rr.com

www.highperformancemachinery.com

MD, E. PA, NJ, NY (Long Island, NYC), DE

Single Source Technologies, Inc.

2 Hagerty Blvd., Suite 300

West Chester, PA 19382

610-430-3670

www.singlesource.com

MIDWEST

KS, W. MO

Gage Machine Tool

10668 Widmer Rd.

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

E. WI

Iverson & Company

441 North 3rd Ave.

Des Plaines, IL 60016

847-299-2461

sales@iversonandco.com

www.iversonandco.com

MI

Methods & Equipment Associates

31731 Glendale Ave.

Livonia, MI 48150

734-293-0660

sales@methods-equipment.com

www.methods-equipment.com

MN, IA, ND, SD, E. NE, W. WI

Hales Machine Tool, Inc.

2730 Niagara Lane North

Plymouth, MN 55447

763-553-1711

sales@halesmachinetool.com

www.halesmachinetool.com

WEST

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street E.

Fife, WA 98424

253-926-6868

sales@ellismachinery.com

www.ellismachinery.com

CO, WY

AME, Inc.

(Adv. Mfg. Eng., Inc.)

5770 Clarkson Street #C

Denver, CO 80216

303-922-9266

www.amerm.com