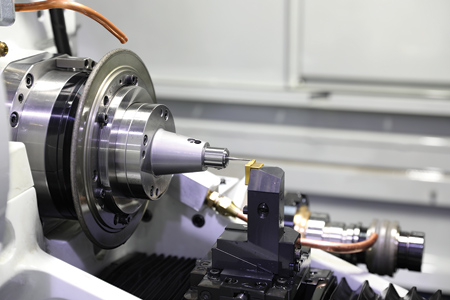

ANCA IMTS MX7linear: ANCA MX7linear CNC grinding machine

ANCA IMTS Robot-AR300: ANCA AR300 3-axis robot system

ANCA IMTS TapXmicro: TapXmicro provides single set-up grinding of micro taps 3 mm and under.

ANCA will feature its latest machine, and visitors will also learn how ANCA's new AR300 robot and RoboMate loader can deliver efficiencies and enable lights-out manufacturing. Other technologies will also be on display.

The new machine was designed in response to customer requests to provide a full range of products to meet all grinding requirements. This new machine complements the FX, MX and TX range.

AR300 Tool Loader

The AR300 tool loader, a 3-axis ANCA robot system, has a capacity of 380 tools and accommodates tool sizes up to O20 mm (O3/4") x 150 mm (6") long. The AR300 loader is contained within the compact FX5 Linear machine footprint. There is no need to change gripper fingers between batches to maximize productivity.

ANCA will demonstrate the AR300 loader in action on a FX5 Linear, allowing visitors to see up-close the tool load/unload capabilities of the loader.

FX5 Linear features include: AR300 loader; iView camera; Auto Wheel Qualification; AutoStick; pop-up steady; and B32/45 precision collet adaptor.

ANCA ToolRoom 2019

ANCA's ToolRoom 2019 version helps users design and manufacture complex tool geometries and get them balanced for optimal cutting conditions.

New at the show is endmill cycles for ballnose and corner radius, tool balancing and next generation fluting cycles. ANCA's new Management Suite, either onsite or in the cloud, is for the CNC grinding industry. It provides customers the technology to monitor the performance of their machines no matter where they are in the world. The new software also enables companies to run smart factories by providing live production information to make data-based decisions on operational improvements.

The latest version of ANCA ToolDraft can create tool and wheel pack drawings within minutes. The CIM3D V8.2 will show how users can get the right balance for variable helix or variable index tools for high speed machining.

TapXmicro

TapXmicro provides single set-up grinding of micro taps 3 mm and under. Grinding micro tolerances with enhanced quality, the TapXmicro achieves a pitch diameter CpK of 1.5 when batch grinding M1.4 x 0.3mm taps with a tolerance of ±7µm.

The TapXmicro is an extension of ANCA tap grinding capabilities, with the versatility to grind taps up to M3. Based off ANCA's MX Linear platform, the 5-axis machine has capacity for up to six wheel packs, dressers for all grinding wheels, and a flexible compensating chuck system between center workholding.

MX7 Linear

ANCA's MX7 Linear is a versatile, next-generation CNC grinding machine designed for production grinding. Its features make it capable of handling varied batch sizes with minimum set-up time. The MX7 Linear is driven by LinX cylindrical linear motors on the X and Y axes. The machine will also be demonstrating the FastLoad-MX, a tool loader designed to enhance the productivity of the MX range of machines.

The FX7 Linear at IMTS will have a range of automation options. On display will be the optional FANUC robot tool loader and 6-station wheel changer (includes changing of coolant manifolds), allowing unmanned capacity for up to 1,092 tools. The LaserPlus option provides automatic laser tool measurement and compensation to maintain a geometric tolerance of +/-0.002 mm over small or large tool batches. There will be a dry-cycle tool production demo of compression routers (up/down cutters), for which the LaserPlus is suited since it measures the O.D. for each of the up cutter and down cutter sections.

All the machine options are contained within the machine's compact footprint, so there is no need for extra floorspace.

The FX7 Linear and its options include FANUC tool loader (with 6 station wheel changer); LaserPlus; iView camera; Auto Wheel Qualification; AutoStick; pop-up steady; and B32/45 precision collet adaptor.

ANCA's LinX cylindrical linear motor is engineered to deliver a surface finish roughness average as low as 0.16 Ra. The smoother surface enables swarf (or chips) to exit more freely, preventing chip packing and material build up during machining. All ANCA grinding machines feature linear motors.

For more information contact:

ANCA Inc.

31129 Century Drive

Wixom, MI 48393

248-926-4466

usainfo@anca.com

www.anca.com

IMTS 2018 Level 3, Booth N-237406