Gear Grinding Platform Includes Dual-Worm Wheels

August 1, 2018

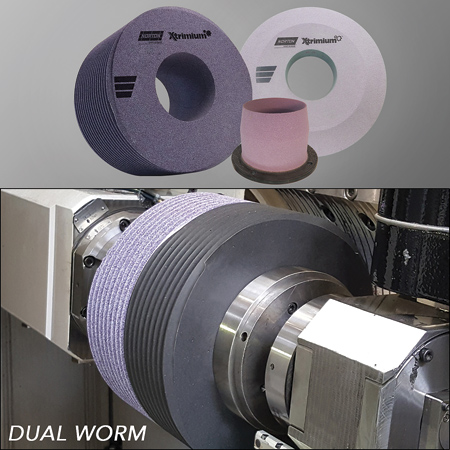

Norton Dual-Worm grinding wheel

Norton | Saint-Gobain Abrasives has announced its new Norton Xtrimium range of gear solutions designed for high performance gear grinding in a tight tolerance environment. The newly structured portfolio of gear grinding products is designed by category to provide higher profile accuracy, enhanced form holding and burn-free grinding in worm, profile, and bevel applications. Highlighting the new range is a dual-worm wheel design that enables two operations in one grinding wheel, saving time and cost.

Norton Xtrimium Dual-Worm Grinding Wheels feature a high-performance vitrified bond section for grinding and a fine-grit resin section for polishing the gear teeth, enabling one wheel to perform what traditionally required two wheels. Improved surface finishes of Rz = 1.0 mm and Rpk = 0.05 mm, and reduced harmonics (noise) are realized. The Norton Xtrimium Dual-Worm Grinding wheels can also be adapted to existing machines.

The Norton Xtrimium Gear Grinding Platform covers the whole range of gear grinding processes to match each customer's requirements:

- Worm Grinding Wheels feature micro-structured ceramic grain and provide free cutting action and wheel homogeneity, allowing constant performance throughout the wheel thickness for the life of the wheel. Enhanced grinding rates and increased form holding without burn are achieved.

- Profile Grinding Wheels suited for deep profile gear grinding. The wheels feature high porosity and permeability, create high material removal rates and friction-free grinding.

- Bevel Grinding Wheels feature a highly porous bevel formation for fast, burn-free cutting.

For more information contact:

Norton | Saint-Gobain

1 New Bond St.

Worcester, MA 01606

254-918-2313

contactsga@saint-gobain.com

www.nortonabrasives.com

IMTS 2018 Level 3, N-237042

< back