Modular Industry 4.0 Solution

December 1, 2018

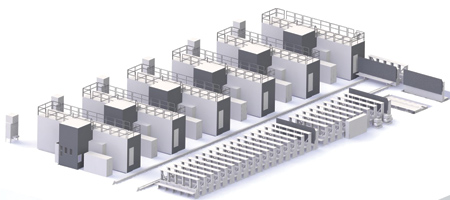

The highlight of the Integrated Production System (IPS) from Starrag is the cell controller developed in-house.

Starrag offers its Integrated Production System (IPS) modular solution, allowing users to select their own individual Industry 4.0 solutions.

"Customers want better profitability, more safety and more growth. That can only be achieved with custom-made, digitized manufacturing solutions," explained Dr. Christian Walti, CEO of Starrag. "With our own IPS and the cell controller technology that we have developed in-house, we are taking the right steps forward. Users and operators can use this technology to control and monitor their Starrag manufacturing systems and production lines to ensure reliable processes. It allows us to support them in the complex task of using data in a networked production world to obtain added value."

The Starrag IPS is used as a platform for automating and digitizing production-step by step if desired. The concept ranges from individual machines, flexible manufacturing systems (FMS) up to complete production lines. "In contrast to other providers, Starrag uses products developed in-house for all important components," said a company spokesperson. "The core element is the cell controller, which monitors FMS and production lines to ensure reliable processes. Not only can it guide and control the entire production process-in conjunction with a higher-level ERP system where applicable-but the cell controller also ensures digital transparency in the factory by visualizing the system status, for example. The in-house developed cell controller is an open system that can be used to link different system components together. This makes it a practical example for customer oriented Industry 4.0 solution."

The IPS platform is based on the customer's individual task to provide the desired added value with a variety of features, systems and services.

Highlights include:

- Internet of Things (IoT): Cloud-based solutions help the customers to analyze and optimize processes more specifically to further increase the availability and productivity of their production.

- Human-machine interface (HMI): Machine operators can use the user interface, developed in-house, safely and without errors due to the touch sensors-even when wearing work gloves.

- Machine Production System (MPS): This system monitors production in real time and protects people and the machine against incorrect operation and collisions.

- Efficiency control: With a number of measures (e.g., reduction in friction due to the use of high-quality drive elements, energy recovery), the holistic concept reduces energy consumption by more than 20%.

- Process Quality Control (PQS): A chatter monitor warns operators of dangerous chatter vibrations when machining critical workpieces, for example integral aerospace components made from aluminum.

- Machine Qualification System (MQS): An integrated fingerprint module informs the owner about the machine condition and, where necessary, displays the corresponding maintenance instructions on the HMI.

Starrag has already used these IPS components to develop interesting and wide-ranging Industry 4.0 solutions together with customers. "One company invested in an FMS consisting of six ECOSPEED F2060 and a two-place rail guided pallet shuttle system that is used to produce a range of aluminum structural components at high levels of effectiveness and efficiency. The solution for Orizon proves that, due to IPS, Starrag can implement custom made digitized production solutions with reliable processes on a large scale," said the spokesperson.

For more information contact:

Starrag USA Inc.

Skyport Business Park

2379 Progress Drive

Hebron, KY 41048

859-534-5201

ussales@starrag.com

www.starrag.com

< back