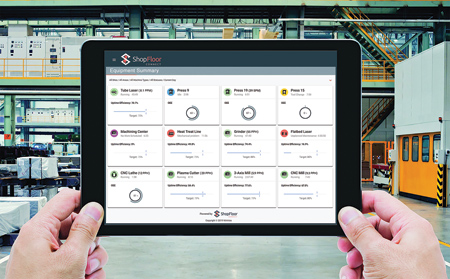

ShopFloorConnect Version 6.0 OEE and Shop Floor Data Collection Software

Wintriss Controls Group offers its new ShopFloorConnect Version 6.0. ShopFloorConnect OEE and Shop Floor Data Collection Software collects downtime and production efficiency data from every machine in the manufacturing operation, displays it in real time and produces manufacturing reports, including detailed OEE reports, in a variety of formats. "The software can significantly increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks, reducing machine downtime by up to 70%," said a company spokesperson.

"ShopFloorConnect Version 6.0 has a new design format for fast, easy access to all data, offering several new features for more robust, user-friendly reporting and dashboard customization, flexible scheduling capabilities and machine interface enhancements, all of which are critical for OEE," said a company spokesperson. "For even better production analysis, users can now improve the OEE of their machines by tracking the reasons for scrap. Version 6.0 also allows users to manually enter good and bad part count data, vital for OEE calculation, when machines with batch processes make it impossible or impractical to automatically count the parts as they are being produced." To better serve customers, this latest program version can handle multiple languages and time zones.

Wintriss also offers its SmartPAC PRO Press Automation Controller featuring a large, easy-to-use touchscreen interface, user-configurable dashboards, virtually unlimited tool set-up storage, the ability to share set-ups among networked SmartPAC PRO units and more.

The SmartPAC PRO tool summary screen enables users to view the entire contents of each programmed set-up on a single screen, providing them the ability to place notes for the job, and all content can be exported to a USB disk as comma-separated values. Users can also create custom home screen dashboards to display the information they use most often. These dashboards can be named and saved in the favorites menu and quickly recalled at any time.

The SmartPAC PRO architecture supports advanced connectivity features such as remote access from PCs and mobile devices, email messaging and compatibility with Wintriss's IIoT production tracking OEE ShopFloorConnect software solution.

A Wonderware hosting option enables the SmartPAC PRO to run independently-created third-party HMIs for associated automation, reducing the number of screens required on the press.

For more information contact:

Wintriss Controls Group

100 Discovery Way, Unit 110

Acton, MA 01720

800-586-8324

www.wintriss.com