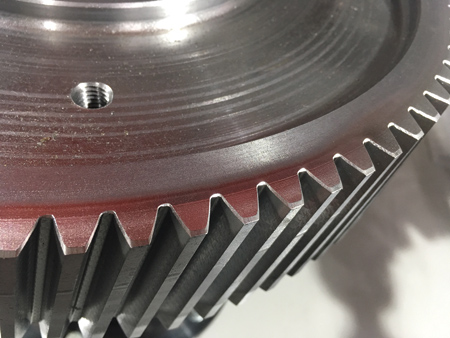

Helios Neo power skiving an internal ring gear

NEOPS 200 power skiving machine

Helios Hera 200 CNC gear hobbing machine (shown with automation)

Hobbing on a Helios Hera machine

Gear deburred on a Tecnomacchine

Helios cutting tools: hobs, shaper cutters, and milling cutters

"While the COVID-19 pandemic has forced IMTS to cancel, Helios nevertheless has announced several new technology solutions," said Adam Gimpert, President of Helios Gear Products. North American gear manufacturers now have the Neo brand of power skiving machine tools; an expanded Hera series of CNC gear hobbing machines that cover micro- to coarse-pitch applications; the TM series of gear deburring machines now with CNC options for flexible productivity; and consumable tools for grinding and cutting applications.

For demanding applications where shaping may be a bottleneck, Helios Neo Power Skiving (NEOPS) machines offer a productive solution for parts up to 420 mm (16.5") diameter and 6 module (4.2 DP). The NEOPS series offers optional features to suit each manufacturer's needs. These include tool sharpening, gear deburring, re-cutting and flexible automation systems.

The Helios Hera series of hobbing machines has expanded to include models 30, 150, 200, 350 and 500. The series uses technical features such as complete FANUC or Siemens CNC, direct-drive torque motors, European digital scales, easy-to-use (and train) dialog programming and versatile unified automation systems. In 2020, Helios introduced the models 200 and 500. The Hera 200 offers most of the 350's technical capabilities but in a smaller body for a decreased physical and financial footprint. The Hera 500 is the series' current largest solution with capabilities for parts over 500 mm (19.685") diameter and 12 module (2.1 DP).

The Helios TM (Tecnomacchine) series of gear deburring machines has added several CNC options. The TM models 200, 250 and 1000 all offer complete CNC options that allow manufacturers to programmatically store and control workpiece and tool parameters, such as spindle speeds, direction and radial, axial, tangential and inclination positions. "For manufacturers that need to recover deburring labor while increasing repeatable quality, the Helios TM series provides profitable solutions," said a company spokesperson.

"For gear cutting, Helios carbide hobs have raised the bar with high quality, low cost and fast delivery," added the spokesperson. "Helios also offers competitive high-speed steel tools, shaper cutters, milling cutters, broaches and power skiving cutters." For abrasives, Helios offers tools for single-profile or continuous generating grinding, honing, dressing and bevel grinding, and the Rex-VTEC series is now available for VSD dressing systems.

For more information contact:

Helios Gear Products, LLC

635 Schneider Dr.

South Elgin, IL 60177

847-931-4121

sales@heliosgearproducts.com

www.heliosgearproducts.com