Aerotech estimates that its Mazak PALLETECH system, with two HCN-5000s HMCs, does the job of eight standalone VMCs that would have required six full-time machinists.

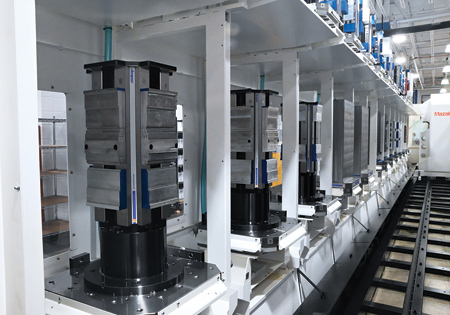

For high-mix operations, Aerotech's Mazak HCN-5000/50S HMCs are part of a 28-pallet Mazak PALLETECH high-rise system that features two loading stations and an overhead gantry loader to automate as much of the shop's processes as possible.

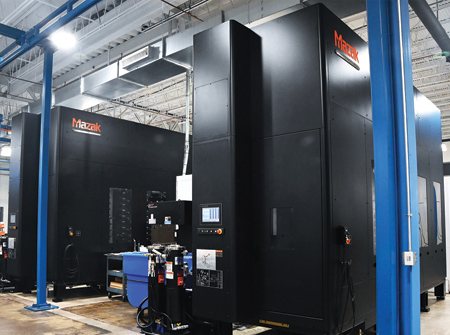

After incorporating Mazak high-precision Horizontal Machining Centers, Aerotech gained the production flexibility to meet all the needs of its medical implant manufacturing customers as well as those in the semi-conductor and other high-tech industry sectors.

Aerotech outfitted its automated Mazak HCN-5000/50S HMCs with Mazak 240-tool toolhives to keep them sufficiently supplied with tooling for unmanned operations.

For Pittsburgh, PA-based Aerotech, making the move from primarily vertical machining centers (VMCs) to horizontals (HMCs) resulted in shorter job lead times, increased spindle uptime and improved output through more lights-out capacity. The shop also gained the production flexibility to meet all the needs of its medical implant manufacturing customers as well as those in the semi-conductor and other high-tech industry sectors.

For its high-mix operations, Aerotech added two Mazak HCN-5000/50S HMCs. The machines with 240-tool toolhives are part of a 28-pallet Mazak PALLETECH high-rise system that features two loading stations and an overhead gantry loader to automate as much of the shop's processes as possible.

"At first, choosing the Mazak horizontals seemed counterproductive," said Anthony Fazzini, Director of Machining at Aerotech. "Those types of machines are typically associated with high-volume production. However, pairing the machines with the modular, pre-engineered PALLETECH system and high capacity toolhives definitely provided us with the job flexibility we needed to reduce set-up times."

Aerotech's automated PALLETECH system gives the shop's machinists the ability to set up numerous downstream jobs while the HCN-5000s continue to run uninterrupted production.

"We estimate our new PALLETECH system, with two HCN-5000s, does the job of eight standalone VMCs that would have required six full-time machinists," said Fazzini. "Equally important, manpower requirements have been reduced significantly. The Mazak system requires only one part-time machinist and one or two full-time operators."

Fazzini went on to say that the ability to set up 28 pallets worth of production in advance has also dramatically improved the shop's automated, lights-out production capability. With the PALLETECH system, Aerotech machinists can set up enough jobs to keep the HCN-5000s running unattended over a long weekend.

Specializing in custom-engineered, high-precision motion and integrated automation systems, Aerotech is the very definition of exceptionally high-mix/low-volume (HMLV) production as well as high volume work. Since 1970, the company has grown from a garage startup into a global automation provider, bringing customer concepts to life, most often in small runs of one to 10 parts of varying sizes and features.

When running its small lot sizes for applications requiring 0.0001" to 0.0002" part tolerances, Aerotech experienced longer-than-normal downtime due to ongoing machine changeovers for each job. In fact, the company found their machine spindles were only running for approximately 10% of their available production time, with the remaining 90% of the time spent on complex set-ups and tool changeovers. However, despite that labor-intensive downtime, Aerotech still managed to turn out some 300,000 parts annually.

It was at this time the shop reached out to Amanda Wiegel, their Mazak Sales Representative and Sales Engineer for A.W. Miller Technical Sales. Aerotech has relied on A.W. Miller as its full-service Mazak dealership for over 30 years.

Through Aerotech's internal machinist training program, the company has also built a strong workforce that is very familiar with Mazak machines and MAZATROL controls.

For more information contact:

Aerotech, Inc.

101 Zeta Drive

Pittsburgh, PA 15238

412-998-7019

www.aerotech.com

Mazak Corporation

P.O. Box 970

Florence, KY 41022-0970

859-342-1700

www.mazakusa.com