CNC Slant Bed Lathe

January 1, 2019

Highly rigid box ways for heavy-duty machining. Slideways are hand scraped, ensuring optimum oil circulation and contact on all way surfaces.

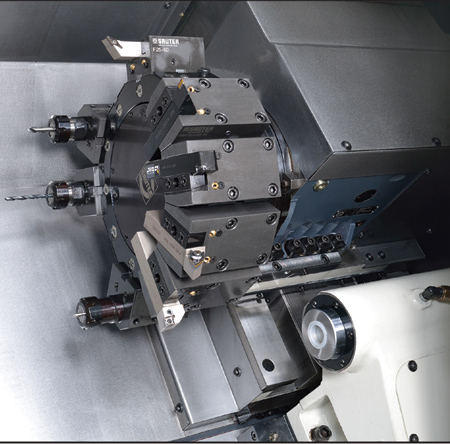

Twelve-station, servo-indexing, live turret offers fast tool indexing.

The FBL-230 and 230MC with live tooling features a 45°, slant-bed, rigid box ways structure. Its ribbed Meehanite cast-iron mono-blocking foundation is designed to provide strong support and damping absorption, which helps resist deflection and vibration during heavy machining.

The FBL-230 and 230MC is engineered with ease of access and trouble-free maintenance in mind. Its compact design minimizes floor space. It is suitable for mixed volume, short-run or dedicated high-volume applications.

Features and benefits:

- Capacity: The FBL-230 and 230MC slant-bed lathe features an 8" chuck, 21.6" maximum swing diameter with up to 12.2" maximum turning diameter and a maximum turning length up to 15.9".

- Spindle: The lathe features a 20 HP, AC digital spindle motor. The spindle bar capacity is 2.04" in diameter, with speeds up to 4,000 RPM. The spindle has cylindrical roller bearings that provide strong cutting capability.

- Turret: 12-station servo indexing live turret offers fast tool indexing.

- Accessories: The standard manual tailstock comes with a programmable quill and a chip conveyor providing efficient chip management.

- Control: Model comes with a powerful FANUC 0i-TF control and digital servo drive and motor. This control features functions that include: a rigid tap, multiple threads and a conversational Manual Guide 0i program.

For more information contact:

Chevalier Machinery Inc.

9925 Tabor Place

Santa Fe Springs, CA 90670

562-903-1929

info@chevalierusa.com

www.chevalierusa.com

< back