Compliant bike seat tailored to pressure map data from the rider. nTop 2.0's Lightweighting Toolkit was used to generate the base lattice onto which the Design Analysis Toolkit imports pressure-map data to further enhance the design and drive lattice density and thickness. Other nTop Platform native capabilities, including spatial grading of geometry, are used to seamlessly blend fully dense and latticed areas as well as regions of round and truncated beams.

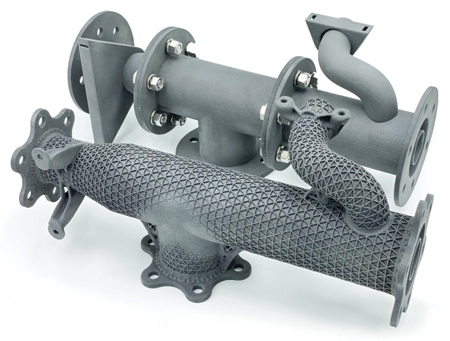

Example of part consolidation using nTop Platform to design a lightweight manifold for additive manufacturing. The original model was an assembly of 42 different parts that were reduced to one single, optimized model. Material was reduced by decreasing the wall thickness and adding a conformal isogrid to maintain structural integrity, as well as topology optimizations of the wall brackets. Performance optimizations include a varied wall thickness in higher-pressure zones as well as varied control over hole diameters in an internal diffuser.

nTopology has announced the latest version of its computational-modeling software, nTop Platform 2.0, an engineering software that enables engineers to simultaneously consider geometry, performance and manufacturability all within a single, reusable workflow. This release includes support for prepackaged, application-specific nTop Toolkits, letting engineers quickly learn and use its powerful capabilities right out of the box.

"nTop Platform was developed to solve engineering problems where geometry is a bottleneck. It can handle complexity and iteration with speed and ease. The prepackaged Toolkits and authoring capabilities can both be used to automate engineering workflows, delivering efficiencies and scaling an organization's best talent across the enterprise. With nTop Platform, teams can automate tasks that take hours, days or weeks with traditional design tools because of the ability to build reusable workflows," said a company spokesperson.

"We are excited to release 2.0 of nTop Platform," said Bradley Rothenberg, CEO of nTopology. "nTop Toolkits enable the best engineering workflows to spread wide throughout industries, making the most advanced modeling technology accessible to any design engineer."

nTopology is also partnering with industry leaders in additive manufacturing (AM) hardware to deliver new capabilities to its users. "The flexibility and high performance of nTopology software and its ability to package-up customer workflows helps us and our customers to create advanced Digital Foam," said Fabian Krauss, Global Business Development Manager at EOS. "We use it in projects to create 3D-printed products with architected materials properties tailored exactly to customer needs. It unlocks the true potential of generative design in AM for Digital Foam and for many other applications."

"In addition to the new prepackaged Toolkits, nTop Platform's authoring capabilities allow a company's most advanced engineers to create their own proprietary toolkits, enabling secure knowledge transfer across the organization," said the spokesperson.

Lightweighting toolkit:

- Quickly and easily reduce the weight and maximize the performance of parts

- Shell parts in seconds no matter how complex the geometry

- Apply variable wall thickness to shelled parts.

Architected materials toolkit:

- Engineer functional materials that perform at any scale-hundreds of unit cells, or hundreds of billions.

- Design with multifunctional requirements from the start. Structural, thermal, acoustics or aesthetics, all with total control at any length scale.

- Optimize unit cells to create unique material properties to suit the application. Increase surface area while reducing weight. Turn geometric complexity into a competitive advantage.

Design Analysis Toolkit:

- Use fully integrated simulation capabilities to seamlessly analyze parts in a single, connected workflow

- Drive geometric parameters directly from simulation results to achieve high-performance parts that meet functional requirements

- Integrate with the simulation tools an organization already uses, including ANSYS, Abaqus and Nastran.

Topology optimization toolkit:

- Discover new and innovative designs early in the product development cycle

- Apply multiple loading conditions and optimize for a variety of performance criteria, including stress, displacement, stiffness and weight

- Use automated geometry reconstruction tools to quickly generate instantly editable geometry.

Additive manufacturing toolkit:

- Position, orient and prepare parts for AM from a set of common build platforms

- Add lattice support structures easily and quickly

- Slice parts avoiding error-prone STL files and export manufacturing data directly to machines.

For more information contact:

nTopology

101 Avenue of the Americas, 12th Floor

New York, NY 10013

917-983-9257

sales@ntopology.com

www.ntopology.com