"From its unique point design to its proprietary, multiphase coating, the HPX drill's innovative design helps manufacturers master holemaking operations in steel," said a spokesperson.

"The HPX drill can run high cutting parameters," said Product Manager Frank Martin. "It lasts longer, generates lower forces and makes better quality holes."

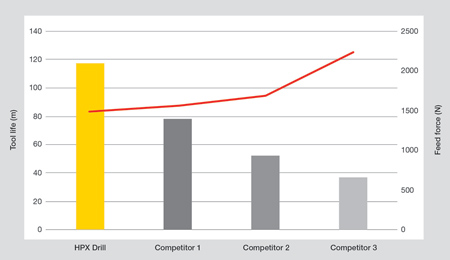

"The HPX drill produces consistently higher tool life in steel than competitive tools, even when feeds and speeds are significantly increased," said a spokesperson.

Kennametal offers an expansion to its solid carbide drilling portfolio. The HPX drill is engineered for high performance, large volume drilling in steel.

"Designed to quickly and efficiently punch holes up to 8xD in any ISO-P steel material, the HPX drill provides up to twice the tool life and three times the productivity compared to competing products, even in dry or minimum quantity lubrication (MQL) applications," said a company spokesperson.

The spokesperson continued, "What makes the HPX drill the superior choice for steel applications is in the design. Steels are used for a wide variety of automotive, commercial and industrial applications, often in production volumes where maximum tool life and throughput is critical. Yet steel creates a high degree of mechanical loading during drilling operations, resulting in forces that lead to rapid tool wear and chipping of the tool's more vulnerable corners. Kennametal has eliminated this failure point by applying a small corner chamfer and straightening the HPX drill's cutting edges. Together with the rounded margin lands running down the length of the flutes, this serves to stabilize the drill while reducing friction."

Built-up edge is another common problem when drilling alloy steels. "The HPX drill's straight cutting edge helps eliminate some of this, but the real clincher is the drill's optimized edge preparation," said the spokesperson. "This gentle hone further reduces the friction that leads to built-up edge, as do the tool's highly polished flutes. Couple that with KCP15B-a proprietary multilayer AlTiN coating designed specifically for steel-and the HPX drill sets a new standard for tool life in high-volume ISO-P drilling."

Special gashing on the HPX drill improves the chip formation and curls a smaller chip. "The material specific HPX point geometry creates lower cutting forces, which works well for machines with lower spindle capabilities, unstable cutting conditions or unstable workpiece clamping. A continuous cross section makes the HPX drill more resistant against tool breakage, and the ultrahigh polished chip flutes offers enhanced chip evacuation," said the spokesperson.

The HPX drill comes equipped with a leakproof MQL interface that meets DIN 6535 and 69090-03 standards.

For more information contact:

Kennametal Inc.

525 William Penn Place

Suite 3300

Pittsburgh, PA 15219

800-466-7738

www.kennametal.com