Automated Press Brake Cell

April 1, 2024

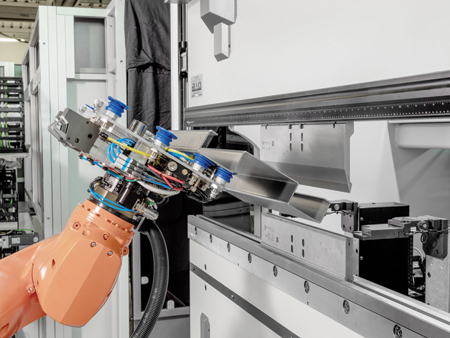

BLM GROUP's ProBend Automated Robotic Press Brake Cell

BLM GROUP has announced its automated ProBend press brake cell. This compact workcell, with an overall size of (LWH) 281" x 162" x 122", features the ProBend E-Series 205-60 and a 30 kg robot. It has the flexibility to process a wide variety of part sizes from 4" x 3" up to 24" x 32" and 33 lbs. with enhanced reliability and productivity. The E-Series 205-60 press brake has a bending force of 66 tons and a bending length of 81".

The system has two load and unload locations with the ability to integrate the unload pallets with an AGV as desired. The pre-load section is configurable for adaptation to part geometry, as well as allowing its removal to accommodate larger parts. The 3-axis Cartesian pick & place system with pivoting head allows the robot to continue processing parts while staging the next piece of material.

The automatic tool change capability requires minimal operator intervention, making tool change between parts fast and easy. With up to six meters of tooling storage, there is ample space for tooling needs. Plus, the system can handle a variety of end-of-arm-tooling types-vacuum, magnet and gripper-style-for processing various types of materials.

The ProBend E-Series press brakes feature a patented, direct-drive system with twin torque motors and an open "C" frame design, providing the ability to form off the edge of the machine. The E-Series, with a ram tilt up to 3/8", offers a generous open height, stroke and throat size, benefiting deep box or special forming needs. Built for optimum accuracy and high speeds on all 6 axes, the E-Series' CNC-controlled backgauge meets the demands of the most complex sheet metal applications for high-production manufacturing. Offline software package gives operators complete control to go from part drawing to pallet in minutes.

For more information contact:

BLM GROUP USA

46850 Cartier Dr.

Novi, MI 48377

248-560-0080

sales@blmgroupusa.com

www.blmgroup.com

< back