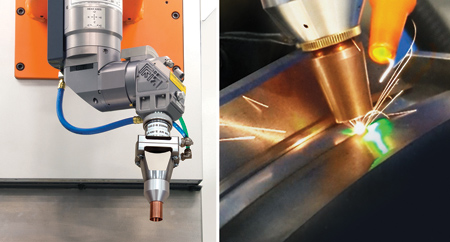

LASERDYNE SmartShield welding nozzle (left), patent pending, simultaneously protects weld metal (right) and beam delivery optics. SmartShield is a new feature for laser welding applications for the 795, 430 BD and 430 Versa laser processing systems.

"LASERDYNE'S new SmartShield welding nozzle provides protection against excessive oxidation in the weld area, enhancing laser welding capabilities of the 3 to 7 axes 795, 430 BD and 430 Versa laser processing systems," said a company spokesperson. "According to previously published welding data, positive results are achieved with effective protection from oxygen in atmosphere during laser welding of a range of materials, which are highly sensitive to oxidation. These include aluminum alloys, copper alloys, titanium alloys, nickel-based super alloys and stainless steels including Types 304 and 316."

SmartShield is the newest addition to the line of proprietary LASERDYNE lens and nozzle assemblies. "SmartShield provides a high velocity gas barrier that prevents metal sparks from the weld zone contaminating the protective lens cover slide," said the spokesperson. "Critical to the SmartShield design is that the cross-jet does not contaminate or otherwise interfere with the welding shield gas. The SmartShield nozzle is designed so that it can be used with an entire range of shield gas delivery devices including welding shoe and coaxial gas nozzle tips.

"The shielding gas shoe provides a controlled atmosphere for the weld zone when molten and while it is cooling to a temperature at which it will no longer be compromised by the ambient atmosphere. This is important for welding materials, such as titanium alloys, that have a strong affinity for oxygen and nitrogen in the ambient atmosphere. An important benefit of this design of the focusing lens/shield gas assemblies for laser welding is that they can be quickly changed to vary the focused spot size or to change from welding to cutting or drilling."

SmartShield is one of the new features from LASERDYNE to support development of new laser welding applications with and without filler metal addition. "Our goal at Prima Power Laserdyne is to continue to produce advancements like SmartShield that expand the use of laser processing and make our customers more successful," said Terry L. VanderWert, President of Prima Power Laserdyne.

For more information contact:

Prima Power Laserdyne

8600 109th Ave. North, #400

Champlin, MN 55316

763-433-3700

lds.sales@primapower.com

www.primapower.com/products/thelaser/