The technological innovations of the ULTRASONIC 20 linear 2nd generation include a digitally controlled ultrasonic generator plus ULTRASONIC actuators with enhanced performance.

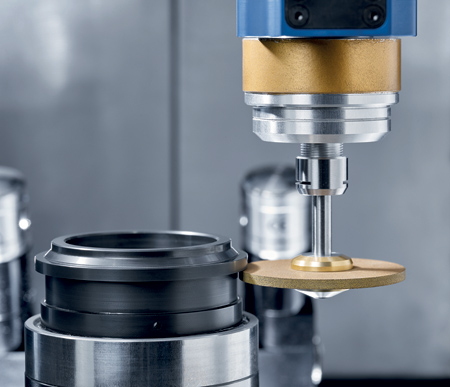

"MT-option" for outer- / inner cylindrical grinding: the ULTRASONIC 20 linear enables complete machining of rotation symmetrical workpieces with grinding and drilling including inner- / peripheral machining in only one clamping

4: Complete machining of an orthopaedic implant made of hipped zirconium oxide

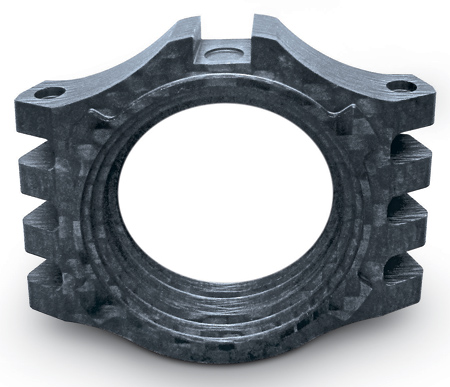

Brake disk

Watch case

Optical components

Dental implants

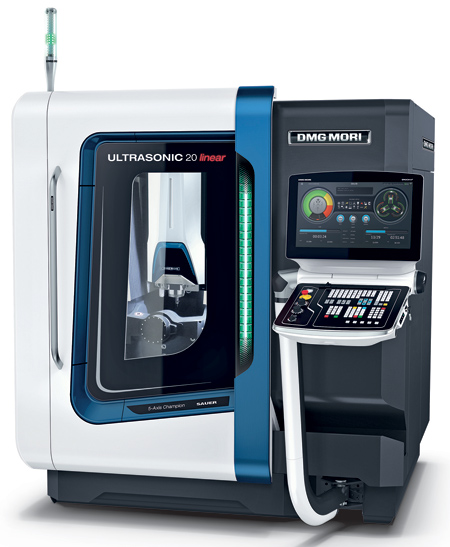

With the ULTRASONIC technology developed in collaboration with SAUER, DMG MORI has for many years been offering machine tools for the high-precision 5-axis machining of complex workpieces made of advanced materials. The series has now expanded with the new 2nd generation ULTRASONIC 20 linear. Optimizations across the board, from the expanded ULTRASONIC technology and the machine construction, the performance and new options available, are designed to enhance the technical edge of the machining center. Spindle speeds of optionally up to 60,000 RPM, more powerful drive motors, an even smaller footprint plus CELOS with apps developed specifically for ULTRASONIC, are among the innovations that users from the optical, clock and watch, medical and high-precision mold construction sectors will be able to benefit in future.

The technological innovations of the 2nd generation ULTRASONIC 20 linear include a new, completely digitally controlled ultrasonic generator plus ULTRASONIC actuators with enhanced performance. The toolholders with adapted actuator technology are changed into the milling spindle automatically. Each of these holders contains piezo elements, which are activated by a program-controlled inductive system with a high frequency of between 20 and 50 kHz. The actual tool rotation is superimposed with an additional tool movement in the longitudinal direction so that a defined amplitude, which can be programed in the NC-program, in the range of up to more than 10 µm is generated on the cutting edge of the tool or on the grinding layer. During grinding, drilling and milling this ULTRASONIC superimposition of vibrations has a direct, positive impact on process forces, metal removal performance and tool service life.

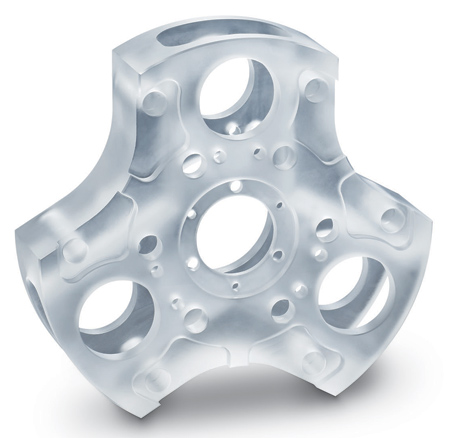

DMG MORI reports that the ULTRASONIC machine results in a higher removal rate, accurate edge machining and up to 40% reduced process forces in the machining of advanced materials such as glass, ceramics, corundum, composite materials and hard metal. Deflections are minimized while workpiece accuracy and process reliability are increased. In addition, this oscillating contact interruption results in better lubrication and cooling of the cutting edge as well as optimum removal of particles from the active zone. This enables longer tool service life as well as enhanced surface qualities of up to Ra <0.1 µ for hard-brittle high-performance materials. The 2nd generation ULTRASONIC 20 linear combines high speed cutting and efficient ULTRASONIC grinding of advanced materials on one machine. It allows the machining of a range of materials.

The smartSONIC is used in the 2nd generation ULTRASONIC 20 linear as a new ULTRASONIC generator. This automatically recognizes the ULTRASONIC frequency that is best suited for actuator and tool. It also tracks the frequency and amplitude power during the machining process. To achieve this, the smartSONIC automatically tracks the frequency response and compensates all external impacts, such as damping of the ULTRASONIC vibrations caused by the prevailing process forces. This results in consistent control of the set amplitude or that defined in the NC-program.

DMG MORI relies on the gantry design for the 2nd generation ULTRASONIC 20 linear in order to meet the demands on precision for ultrasonic machining. Whereby the machine tool manufacturer was able to reduce the footprint to a compact 37.7 sq. ft. A duel drive in the Y-axis and the integral cooling concept that includes temperature monitoring of drives and spindles as well as the control cabinet and all media are engineered for precision and component accuracy. The linear scales from Magnescale are another example of the components used by DMG MORI.

DMG MORI reports it has increased the performance of the drives in its latest development: by 47% in the A-axis, 27% in the C-axis and 34% in the Z-direction. The linear drives achieve maximum accelerations of >1.2 g and a 2,000 IPM rapid traverse. With the large swivel range in the A-axis of the work table of -15° to 130° and the fully integrated infinitely rotating 360° rotary axis - both with torque technology - the 2nd generation ULTRASONIC 20 linear is equipped for flexible 5-axis simultaneous machining. The up to 1,500 RPM available as an option for the C-axis helps to enable cylindrical mill-grind and mill-turn operations.

After its revision the 2nd generation ULTRASONIC 20 linear is now also capable of handling larger tool diameters of up to o 2.0". It has also been possible to increase the workpiece weight from 22 lbs. to 33 lbs. The standard version is equipped with a 19 kW motor spindle, HSK-32 tool holder and 42,000 RPM. Higher speed requirements are met with an optional spindle that offers 60,000 RPM. An HSK-40 spindle, optionally with permanent grease lubrication, rounds off the offer.

DMG MORI's modular concept allows application-specific equipping of its machines, also in the case of the 2nd generation ULTRASONIC 20 linear. The machine is also available with a 1,500 RPM mill-turn table, for example, which expands complete machining to include milling, turning and grinding of rotational-symmetrical components in a single set-up. In addition to the standard 24-fold tool changer with pick-up, the chain magazine is optionally available for 60 tools.

In particular, the 2nd generation ULTRASONIC expands the use of ultrasonic assistance to applications with a defined cutting edge - in particular the milling and drilling of nickel or titanium-based superalloys or materials such as magnesium, tungsten and composites. DMG MORI reports that process forces have been reduced for milling applications in titanium alloys by up to 30%. Feedrates for steel can be doubled. For other materials, such as magnesium, these rates can be increased in part by anything up to five-fold. In addition surfaces are also better. ULTRASONIC has a special effect on chip breaking and the removal of chips on the tool. The chips break shorter and tool wear is reduced.

Long-lasting exterior covers and improved accessibility are features of the new DMG MORI joint design. It is also equipped with CELOS. This uniform user interface with its multi-touch screen is as simple to operate as a smartphone. This user-friendliness is further boosted by CELOS apps developed specifically for ultrasonic machining, which visualize ULTRASONIC technology cycles and key process parameters such as frequency, amplitude and output. These apps also monitor the process forces of the actuator and aid setting up of the tools.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI (364-6674)

www.us.dmgmori.com