The technology used in a TRUMPF TruDisk disk laser is designed to withstand laser radiation reflected from the workpiece.

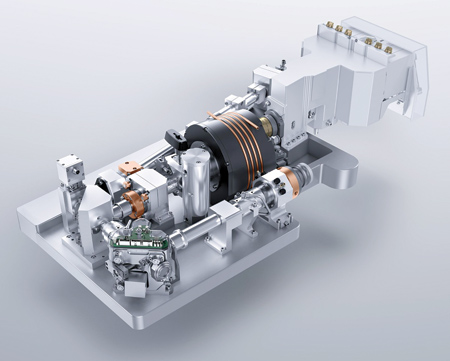

New-generation TruDisk disk lasers are extremely compact, with a footprint of less than one square meter.

The mirrors in the optical cavity guide the pump beam emitted by the diodes through the disk crystal multiple times.

TRUMPF offers the latest generation of its TruDisk disk laser. This new generation of disk lasers features built-in intelligence, offering optimum hardware features for a digitalized future and Industry 4.0. The ability to carry out condition and trend analyses - also known as condition monitoring and predictive maintenance - is a basic prerequisite for implementing lasers in digitalized and connected manufacturing environments.

"The new TruDisk is not just the smartest, most advanced generation of disk lasers we have developed, it is also the most compact and energy efficient," said Klaus Löffler, Managing Director and head of sales at TRUMPF Lasertechnik GmbH. "Combined with our Condition Based Services for condition and trend analyses, the new TruDisk lasers are the perfect production tool for superior Industry 4.0 production lines." Condition Based Services are a modular component of TruConnect, the TRUMPF technology for connected manufacturing and Industry 4.0. They increase the availability and productivity of connected laser systems while identifying potential cost savings.

The critical hub of the smart TruDisk beam source is the built-in control system known as CPX. This is the laser's brain, where all the condition data and process parameters are collected. During processing, a broad array of sensors measure multiple parameters, including the actual laser output at microsecond intervals, all internal and external signal characteristics, the utilization rate of the beam source, and the condition of additional components. The new generation of TruDisk lasers also incorporates a feature that enhances the quality of the data obtained from the readings. Known as Precision Time Protocol, this feature synchronizes all the sensors and provides them with an identical time stamp. With customer's prior approval, Condition Based Services will be used to analyze data parameters, carry out algorithm-based trend analyses and take targeted measures to determine the risk of potential laser failure in advance and prevent unscheduled downtime.

The second major improvement inside the new-generation TruDisk lasers can be found in the new laser diodes, which TRUMPF develops and produces at its U.S. plant in Princeton, NJ. The new laser diodes are both compact and energy efficient. "That keeps running costs down while also reducing the laser's footprint, which - at 0.85 square meters - is currently the benchmark for multi-kilowatt high-power lasers," said a company spokesperson. There is even room in this small space for the laser's smart cooling system, which enables the use of cooling water at feed temperatures of up to 26 °C. This eliminates the need for an external cooling unit in many cases.

TRUMPF has increased how efficiently the lasers work and equipped them with a new pulse function. This makes it possible to ramp the current of the pump diodes down to zero amps even during very short laser-off times between two processing steps. The new generation of lasers comes with a smart energy management system that switches the laser between different power-saving modes for each operation, reducing energy consumption. The disk laser's optics have also been redesigned to ensure optimum use of the diode pump light.

The TRUMPF TruDisk laser's real-time power regulation ensures the power applied to the workpiece remains stable from one operation to the next and throughout the system's entire service life. TruDisk technology is designed to withstand laser radiation reflected from the workpiece. It also offers a modular design, for upgrading to machines with individual components and functions. "This disk laser is designed to tackle a range of applications," said a company spokesperson. "From auto making, aerospace engineering, medical devices and electronics, to the supply sector and heavy industry, the high beam quality of a TruDisk laser makes it a reliable tool for joining, coating, additive manufacturing, hardening and cutting with high quality and reproducibility."

The new generation of TruDisk lasers is available for laser outputs of between 3 and 5 kW with fiber core diameters between 100 and 600 µm.

For more information contact:

TRUMPF Inc.

Farmington Industrial Park

111 Hyde Rd.

Farmington, CT 06032

860-255-6000

info@us.trumpf.com

www.us.trumpf.com