The new »eQ« Plus single-hand operating device offers enhanced user comfort and an additional functional button

»venturion 450« features enhanced ergonomics

»smileCompact« entry-level model

Choose between measuring ranges for a maximum tool length of 350 mm to 800 mm and tool diameters from 320 mm to 620 mm with »smile«

"The secure tool data transfer to the machine is proven and tested and independent of the machine tool manufacturer," said a company spokesperson.

ZOLLER offers the »venturion«, »smileCompact« and »smile« presetting and measuring devices in a new design featuring optimized ergonomics and comprehensive hardware and software functionality to provide precise measuring results for every tool.

The functional design of the »venturion 450« operating elements, and the ergonomically designed separate »cockpit« operating unit provide operating comfort. The redesign of ZOLLER's classic »eQ« Plus single-hand operating device features adapted form and integrated LED light. It enables preprogrammed functionalities like spindle clamping using the newly included function button.

The »venturion« offers flexibility and precision. "With features such as the »ace« high-precision spindle, a high-end camera for even the smallest tool geometries, options such as RFID technology for reliable process data transmission, and comprehensive software capabilities, this device offers the right presetting, measuring and inspection solution for every application," said the spokesperson.

The new »smileCompact« is designed for small operations or as a second device for simple, efficient tool presetting.

The »smile« accommodates measuring ranges of 350 mm to 800 mm maximum tool length and tool diameters of 320 mm to 620 mm. A choice of three image processing technologies are available: »pilot 1.0«, the basic version for simple presetting and measuring of standard tools; »pilot 2 mT« with modern touch-operation technology and user-specific menu guidance; and »pilot 3.0«, which covers the entire bandwidth of tool measuring, inspection and management.

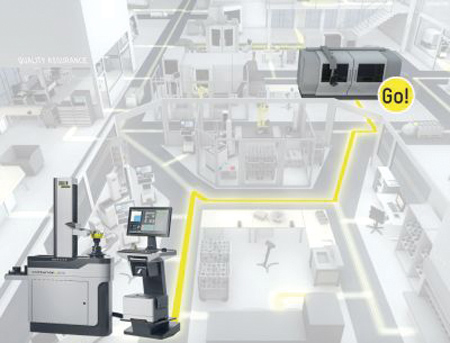

All presetting and measuring devices are ready for networked manufacturing of the future. Process security is offered, via intelligent software developed in-house.

The system securely and reliably transmits tool data to machines made by any manufacturer, and commonly available third party systems. From ERP and CAM systems, to cabinet and lift systems, all can be networked with ZOLLER.

For more information contact:

Zoller Inc.

3753 Plaza Drive

Ann Arbor, MI 48108

734-332-4851

sales@zoller-usa.com

www.zoller-usa.com