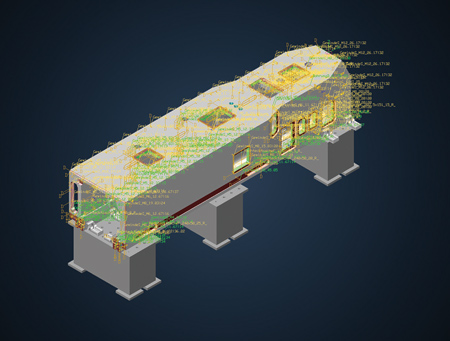

For this complex part, Tebis Version 4.0 Release 5 automatically selects the total of 705 tools for collision-free machining of the 270 features in just two minutes - a time savings of 80% in comparison with the previous version.

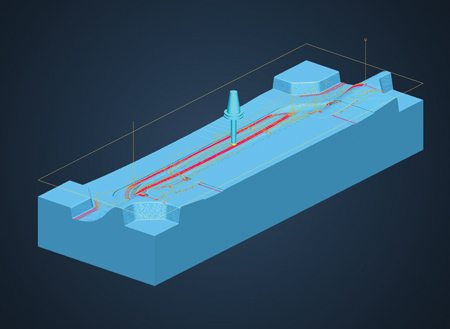

On re-roughing this mold component, the new version can save the user up to 60% in calculation time.

Tebis America, a software company specializing in CAD/CAM systems for design and manufacturing, servicing the tool, die, mold, automotive and aerospace manufacturing industries, has announced the latest Release 5 of its Version 4.0

Tebis has especially optimized the performance of its software with the current Version 4.0, Release 5. This helps users accelerate their processes without functional restrictions. Examples include machine simulation, working with tool sets, searching for tools in feature machining or exchanging tools in the Job Manager.

With the new release, NC programming is now largely automated based on templates with process libraries that enable fast and reliable procedures and processes. Users can also easily edit large and complex parts with Tebis.

"Convenient and powerful technologies place large demands on computing resources and can easily affect performance," said a company spokesperson. "Tebis has identified that the heaviest loads occur in specific processes - the so-called bottlenecks that can result in long waiting times, as well as heavy use of resources and conflicts. The Tebis developers then adapted the system to optimize the use of all available memory." Multi-core technology relying on parallel processing was simultaneously integrated.

The extended parallel processing now used is engineered to save time, especially in the calculation of NC programs for re-roughing. Parts can be loaded, shaded and saved with time optimization.

For more information contact:

Tebis America

400 E. Big Beaver Road

Troy, MI 48083

248-524-0430

info@tebisusa.com

www.tebis.com