Entirely 3-D printed prototype (apart from the internal springs), produced with the parameter set. It enables EOS customer Exactech to create instrument solutions in small production runs with reduced lead time and cost.

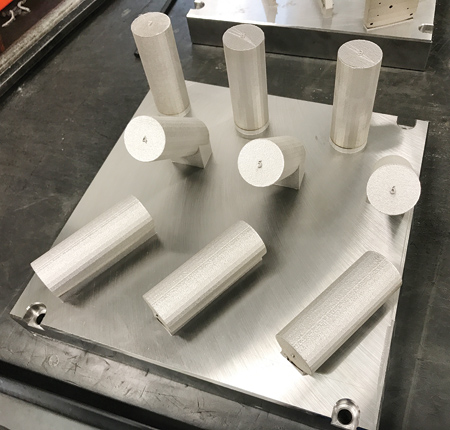

Nine cylinders on the EOS M 290 build plate. ITAMCO prepared the build of nine cylinders with Sunata software by Atlas 3D.

New materials for industrial 3-D printing typically require elaborate tests and qualification processes that extend the period of time before it is used for serial production. EOS, technology supplier in the field of industrial 3-D printing of metals and polymers, addressed this concern for its customers by creating , a metal alloy powder and specific process parameters for manufacturing on the EOS M 290 metal system.

" meets the essential requirements of serial production using additive manufacturing (AM), guaranteeing reproducible part quality through the highest degree of data reliability capable for material properties," said a company spokesperson. "The technology enables users to save time and cut costs considerably in the areas of downstream quality assurance and part qualification."

Tobias Abeln, Chief Technical Officer at EOS, explained, "Planning security and reliability are top priorities for customers who are engaged in serial manufacturing. For its StainlessSteel 17-4PH IndustryLine, EOS provides reliable and statistically proven data for the most important material properties of finished parts."

Abeln continued, "This significantly raises quality standards in AM. The customer can use the data 1:1 to qualify the technology for large-scale production and therefore minimize the time required as well as cut the cost of in-house material and process qualification."

is a high-strength, easily curable, highly corrosion- and acid-resistant material, making it suitable for manufacturing surgical and orthopedic instruments. This material also withstands post-processing of 3-D printed parts such as micro-blasting and polishing.

The existing material data sheets and batch-specific material test certificates contain extensive information regarding product testing and material standards. These either correspond to international standards or EOS in-house quality assurance procedures where international standards are absent. The quality of each batch of powder delivered is offered by quality assurance processes derived from the extensive quality management system used at EOS for systems, powdered materials and processes.

ITAMCO AM Parts Outperform 17-4PH Stainless Steel

Indiana Technology and Manufacturing Companies (ITAMCO) has additively printed parts made with EOS 17-4PH IndustryLine metal powder that outperformed 17-4PH stainless steel in tensile strength in a recent research project.

The goal of the research project was to explore the properties of AM parts made with the new metal powder for direct metal laser sintering (DMLS). ITAMCO prepared the build of nine cylinders with Sunata software by Atlas 3D. Sunata automatically chose the best orientation for the parts and generated the necessary support structures for the build on ITAMCO's EOS M 290 3-D printer.

Three cylinders were built horizontally, three were built at 45° to the horizontal, and three were built vertically. After the build, the cylinders were cut from the build plate and sent for heat treatment. The heat treatment followed the recommended steps by EOS. First, the cylinders were heated to 1,040° C and kept at that temperature for 0.5 hour. The cylinders were then quenched by argon. After that, the cylinders were reheated to 480° C and kept at the temperature for one hour. The cylinders were quenched again by argon. The hardness was between 40 and 47 HRC and the estimated tensile strength was 190 KSI after heat treatment.

The cylinders were then shipped to SGS MSi, a metallurgical testing laboratory. The key results for ITAMCO were the tensile strength (PSI) numbers: The tensile strength of the nine cylinders outperformed the tensile strength of raw material 17-4PH that had been heat treated. The average tensile strength (PSI) of the nine cylinders was 192,000. The average tensile strength (PSI) of six heat-treated stainless steels (H900, H1025, H1075, H1150, H1150-M, H1150-D) is 144,000.

"We conducted the research so we could compare the wrought properties of metal to parts made through AM with the new EOS 17-4PH StainlessSteel metal powder," said Joel Neidig, Business Development and Technology Manager, ITAMCO. It is quite amazing to us that we achieved the wrought properties of metal."

Another interesting finding from the research was that although the nine cylinder samples were built with three orientations, the tensile strength, yield strength, elongation and reduction of area were fairly consistent for all the samples. In other words, the material properties are near isotropic for those samples built additively with different build orientations in the EOS M 290 3-D printer.

ITAMCO is building AM parts for the medical device market; therefore, the EOS metal powder is of particular interest to the company. is a high-strength, easily curable, highly corrosion-resistant and acid-resistant material, making it suitable for manufacturing surgical and orthopedic instruments. However, the product will also be used to build gears and related components for ITAMCO's customers in mining, oil, gas, aerospace, automotive and energy.

"ITAMCO is running the balanced triangle-the combination of 17-4PH IndustryLine metal powder, the grid nozzle for optimized Argon gas flow and the scanning parameters provided by EOS," said Laura Gilmour, Global Medical Business Development Manager with EOS North America.

For more information contact:

EOS of North America, Inc.

28970 Cabot Drive, Suite 700

Novi, MI 48377-2978

248-306-0143

info@eos-na.com

www.eos.info

ITAMCO

6100 Michigan Road

Plymouth, IN 46563

574-936-2112

info@itamco.com

www.itamco.com