Modular Mechatronic Systems

December 1, 2014

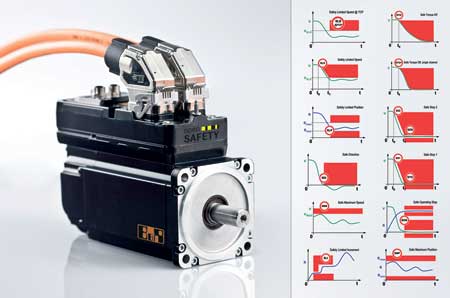

An ACOPOSmotor combines the motor, drive and safety technology in a single unit.

With the ACOPOSmotor, B&R Industrial Automation Corp. combines a servo motor and drive in one compact unit. Safety technology can also be integrated as an option. According to the company, this gives developers more freedom when designing a machine and can save valuable space in the control cabinet.

The ACOPOSmotor is connected to the drive network using a hybrid cable. This cable includes all necessary power and signal lines and establishes the connection to the POWERLINK network. ACOPOSmotor modules come in three sizes with torque ranging from 1.8 to 12 Nm. If needed, an optional fan assembly can provide a performance boost of up to 100%.

In addition to the wired safety functions, Safe Torque Off (STO) and Safe Operational Stop 1 (SS1), a network-based ACOPOSmotor module variant will also be available in the future. As with the ACOPOSmulti, this will allow users to access the following functions: STO, SOS, SS1, SS2, SLS, SMS, SLI and SDI.

The ACOPOSmotor is fully compatible with the ACOPOSmulti drive system. According to the company, this makes it possible for users to select the best-suited servo drive for each machine without having to do any additional engineering work.

For more information contact:

B&R Industrial Automation Corp.

1250 Northmeadow Parkway, S-100

Roswell, GA 30076

770-772-0400

www.br-automation.com

< back