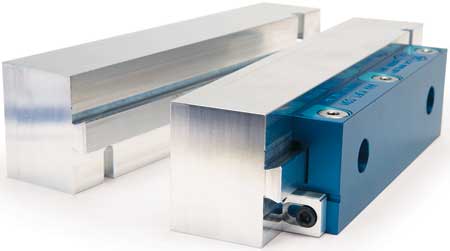

Short throw shifters (left) for high-end sports cars from MGW Ltd. are precision machined in Kurt vises equipped with the latest DoveLock jaw system (right). Jaw set-up time is reduced 75% compared to a previously used jaw system.

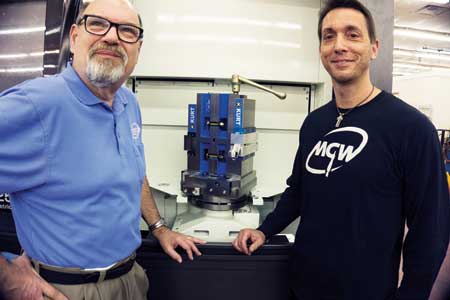

Bob Gesuelle (left), Kurt Sales Representative and President of Machine Tool Accessory Sales, recommended the DoveLock system to George Ciamillo (right), of MGW, Ltd. as a way to reduce job set-up time.

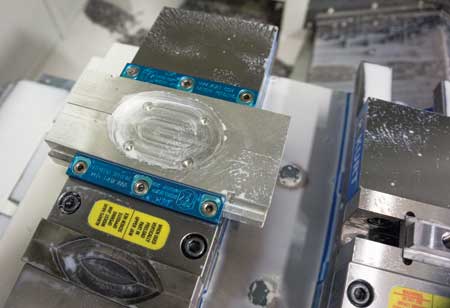

The DoveLock system is shown mounted in back-to-back Kurt Model 3620V vises. They provide a flexible workholding platform for machining many different parts in varying lot sizes.

"Changing the DoveLock jaws is fast while giving new life and purpose to existing vises and towers," said a Kurt spokesperson. "Machine operators like using them because of their simplicity and ease of operation."

MGW's shop-wide change to the Kurt DoveLock system included the majority of its vises and towers. This DoveLock set-up is used to precision mill a form. With many small lot part runs, MGW optimizes operator set-ups over several machining centers, enabling faster customer deliveries.

George Ciamillo of MGW, Ltd. pictured with a demonstrator shifter connected to a transmission housing.

MGW Ltd. has proved that the jaw system used in a workholding set-up can make a huge difference in productivity. By making a shop-wide change to the Kurt DoveLock quick-change jaw system in its machining operations, the company reduced job set-up time by 75%, improved quality and virtually eliminated scrapped parts.

"The improved productivity started immediately when we began using the DoveLock," reported George J. Ciamillo, Vice President of MGW, Ltd. "It is a simple to use system for our machine operators. They improved set-up time by 75%. We did that without compromising part accuracy because the DoveLock gives us jaw positioning repeatability up to +/-0.001."

Repeat Short Runs a Challenge

MGW Ltd. is a high-end automotive aftermarket manufacturer of short throw shifters for domestic sports cars including Corvette, Mustang, Viper, Camaro and others. These are custom designed shifting devices. They provide precise operation and feel with an elegant appearance appreciated by sports car aficionados who demand only the best. MGW has numerous patents on its shifter designs with many of its products officially licensed by Ford and Chrysler.

With a history in CNC machining dating back to 1984, MGW operates numerous Okuma and YCM horizontal machining centers (HMCs) and vertical machining centers (VMCs). The company initially did contract machining for the firearms, aerospace and microwave industries and has certifications in these areas. But the short and repeat part runs for the shifter products mandated more efficient workholding set-ups, moving the company to new workholding with the DoveLock system.

"One of our biggest challenges was to find an efficient way to switch from one shifter set-up to another quickly to save on costly machine down time," said Ciamillo. "We needed accurate workholding that did not need to be indicated every time we set up for a repeat job."

A New Workholding Solution

As a longtime user of Kurt workholding products, when MGW purchased a new Okuma HMC, the company equipped the machine with Kurt CarvLock towers integrated with dual station 6" capacity vises. After a visit there to see the new set-up, Bob Gesuelle, Kurt Sales Representative and President of Machine Tool Accessory Sales, forwarded Ciamillo information on the newly announced Kurt DoveLock system. Ciamillo immediately saw the benefits, reviewed the online DoveLock videos and ordered 20 DoveLock jaw systems.

"Prior to the DoveLock quick-change jaw system, we were using custom machined blank jaws," said Ciamillo. "They required time-consuming leveling, indicating and locating every time we set up a job. It did not take rocket science to figure out with our many repeat short runs that the DoveLock really was a workholding improvement."

How the DoveLock Solution Works

MGW knew that no matter how fast a CNC machine operates, if set-up time is not minimized, the overall machining production time and cost is too much. It comes down to what jaws are used in the set-up.

DoveLock consists of a master jaw with built-in, specially designed dovetail quick clamps. The quick clamps are designed to precisely hold and lock into position the quick-change machinable jaws. In the initial set-up, each master jaw has two bolts that fasten easily to the stationary movable jaw of any standard 6" Kurt vise and standard Kurt Cluster Tower. Once the master jaw(s) are in place, the machinable jaws locate precisely with the master jaw and quickly lock up using the master jaw's three quick clamp bolts.

DoveLock's machinable jaws swap out easily for future jobs simply by loosening the three quick clamp bolts at the top of the master jaw and sliding it forward at an angle or sideways out of the master jaw. "Another nice feature - unique to the DoveLock - is that the machinable jaws can be rotated 180° and machined on both sides for holding two different parts," said a Kurt spokesperson. "Without measuring, DoveLock's workstop, located on the master jaw, allows for quick and repeatable location accurate to +/-0.001 inch." To handle a full range of part sizes, interchangeable jaws are available in 6", 7", 8" and 10" widths.

Ideal Method for Upgrading

MGW had a substantial investment in its workholding so it wanted to preserve that as much as possible. The DoveLock system stood out as a way to improve set-up time with its existing vises and towers while adding versatility for handling frequently changing jobs.

Operating an eight-hour, five-day workweek, MGW produces hundreds of shifter parts, including shifter bodies, brackets, linkage arms and other machined components, mostly machined from aluminum. Using the previous jaw set-ups, MGW would go through two to three runs per set-up to get its first acceptable part. Now, with DoveLock, the jaws usually yield an acceptable part on the first operation, reported Camillio.

With thousands of these parts machined a week, MGW said "it realized an improved spindle time of at least 10%. That is operating both HMCs and VMCs at 5,000 - 12,000 RPM and feeding at 50 - 200 IPM."

MGW machines the DoveLock jaws in place and gets repeatability within .001". Compared to the old method, MGW noted that the DoveLock jaws are also easier to mark and group in fixture bins for faster retrieval. They do not have boltholes so the fixtures stay free of dings and dents.

New Workholding Versatility

An additional DoveLock advantage allows milling into the changeable jaw plates using the full volume of jaw material. With previous jaw set-ups, it was necessary to avoid the two cap screws when machining a feature or pocket into the jaw plate. Utilizing that extra area of metal, the DoveLock allows workholding set-up designs that were previously not possible.

The DoveLock jaws also give users the ability to machine multiple steps on the same pair of jaw plates. Rotating the jaw plates allows the machining of different steps on both sides, so fewer jaw plates are required. Also, because of the DoveLock's machined jaws precision, operators can accurately clamp wider parts into two side-by-side sets of jaws.

"The Dovelock quick-change jaw system provides a perfect grip and precise repeatability for very accurate and consistent machining," stated Ciamillo. "The system allows us to utilize our machines to their full capabilities while maintaining consistent part quality. We were able to preserve and upgrade our workholding throughout our manufacturing operations at a reasonable small investment."

DoveLock is available as a two component system consisting of: two master jaws with four low head socket cap screws and a 5/32" hex "T" wrench; and a machinable jaw set consisting of two machinable aluminum jaw plates. The DoveLock Master Jaw System is available in both inch and metric sizes and is precision-machined from 6061 aluminum for precise and repeatable set-ups.

For more information contact:

George Ciamillo

MGW, Ltd.

4159 Mike Padgett Highway

Augusta, GA 30906

706-793-1770

mgwltd@mgwltd.com

www.mgwltd.com

Kurt Manufacturing Company

Industrial Products Division

9445 East River Road NW

Minneapolis, MN 55433

877-226-7823

workholding@kurt.com

www.kurtworkholding.com