Innovative Hydraulic Press Solutions

October 1, 2020

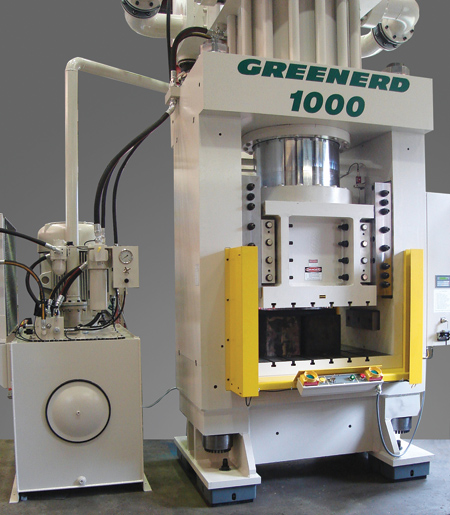

Greenerd 1,000-ton hydraulic press sized for 110 tons per square foot.

Greenerd offers a variety of hydraulic press application solutions, including a 1,000-ton hydraulic press that is used in a coining operation for forgings. The 1,000-ton press is sized for 110 tons per square foot and features a 30" x 30" bed size. The press is gib-guided to handle off-center loading. A safety light curtain package is also provided.

"To meet the demands of today's challenging applications, we are providing manufacturers with press solutions that are flexible, productive and reliable as well as often being quite large and complex," commented Greenerd Press & Machine Company CEO Jerry Letendre. "For even greater manufacturing efficiency, we are able to provide our hydraulic press customers with turn-key, state-of-the-art robotic product handling solutions."

Greenerd is a Tier 1 Industrial Authorized Robot System Integrator of FANUC America Corporation. The partnership gives Greenerd full access to the comprehensive offerings of FANUC robots including all models, training and support, providing state-of-the-art automation solutions in short time frames. Complete, fully integrated production systems can be provided including simple raw material feeding systems, and robotic solutions including loading/unloading the press, the ability to perform an optional secondary part manipulation or process, automated inspection of parts and stacking finished products for downstream processes. The scope of automation can also encompass part inspection systems, ranging from small sensors to complex camera inspections, and temperature monitoring/control of press and non-press related systems. Streaming critical production data to and from the press is also offered.

Greenerd's extensive line of hydraulic presses are available in a variety of styles ranging from gap frame and straight-side to die-spotting and forging presses, with unlimited size and tonnage capabilities. Greenerd has a long tradition of designing, engineering and manufacturing customized hydraulic presses with product handling solutions.

For more information contact:

Greenerd Press and Machine Co.

41 Crown Street

P.O. Box 886

Nashua, NH 03061

800-877-9110 / 603-889-4101

sales@greenerd.com

www.greenerd.com

< back