(l-r) Lyle Anderson, Geoff Bamber and Charles Gohlich, C & H Machine and EDM Services, with a DMG MORI DMU-50.

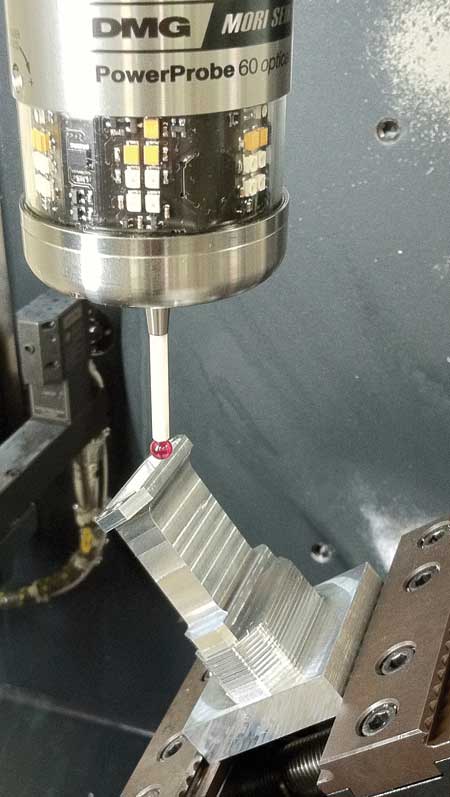

The DMU-50 machine tool touch probe performs in-process inspection.

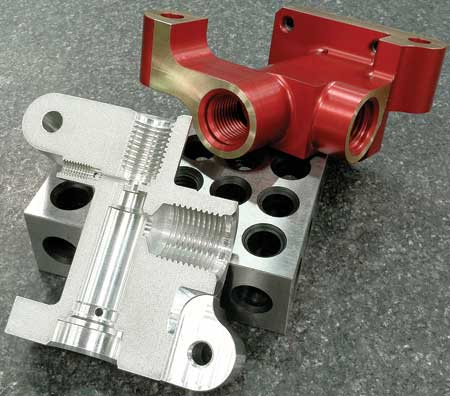

A close up of the inside of a fuel management manifold for an aerospace application. This part was cut in half with wire EDM for inspection purposes.

Cutaway of a fuel management manifold alongside a finished one that has been anodized. The part was made complete in one 5-axis mill operation and one 3-axis mill operation.

Geoff Bamber, Programmer/Machinist, performs a touch probe measurement cycle on one of the company's DMU-50s.

The engineering team at C & H Machine and EDM Services were dissatisfied by historically underutilized spindle time opportunity on the company's 3-axis machining centers. The team also was challenged to do more complicated parts with closer tolerances, which required more sophisticated set-ups and tooling. "Our best set-up resources were being limited in the shop because they were being overwhelmed by the demands of making new fixtures and operating jobs that were so challenging it was considered too risky to turn these over to mid-level operators," said Lyle Anderson, President, C & H Machine and EDM Services. "These more exacting jobs actually caused a loss in throughput throughout much of the shop."

C & H Machine, a job shop machine shop with major emphases on milling, turning and wire EDM, has long been heavily invested in 3-axis machining centers. The company had recently invested in a multi-pallet vertical milling center and a horizontal with some quick-change workholding. While these brought important and beneficial levels of efficiency, they did not alleviate the major issues of throughput within the milling portion of the shop.

C & H Machine chose as a solution two 5-axis mills from DMG MORI through Ellison Technologies, who also introduced the company to HyperMILL programming by Open Mind. They offered a turnkey approach with help in training and applications for the machines, tooling and programming software. "Without that assurance from Ellison, we would have been hesitant to make the investment, not wanting to end up with more unrealized potential," said Anderson. "Furthermore, we chose to start with two machines, to be delivered within a few months of each other, because we wanted to leverage the technology to really impact a practical and cultural change in our shop."

According to Anderson, Ellison Technologies' full-service applications team made good on their promise to provide help where needed. "After a year and a half we are very successful at confidently taking on more work with demanding features and tolerances while alleviating stress on our talented set-up people," said Anderson. "On those jobs we now spend less set-up time and we can have operators run proven jobs with great confidence. Furthermore, the angles of access we have to parts afforded by the 5-axis machines allow us to actually remove material faster - not to mention nearly eliminating much of the set-up and fixturing time."

Another major benefit of the DMG MORI DMU-50s paired with the software from Open Mind is application. C & H's 5-axis programmer, Geoff Bamber, said his "only limiting factor is his imagination. If we can dream it, chances are we can machine it." In a short period of time several new jobs have come in that, in a 3-axis world, would have been inconceivable to manufacture. "When seen from a 5-axis perspective, these jobs became not only simple, but also turned into a great revenue generator for the company," said Anderson. "Some of our more difficult repeat jobs have also been switched to our 5-axis department. These jobs now take between 40% - 70% less time to manufacture. Five-axis machining has definitely given us an edge competing in a global market.

"It is well established that 5-axis machining with state-of-the-art equipment is ideal for saving set-up time and for consistently achieving stricter tolerances with faster throughput, but there is one less tangible appreciation for this technology that I would like to emphasize. Not only can our estimators confidently quote to take on complicated jobs and not worry about whether we can get the job delivered on time, but our machinists are no longer sweating out and wasting time nursing the last set-up, hoping not to lose all the time invested in the parts due to a stack up of lost tolerances from all the earlier set-ups. Five-axis is a stress reliever."

The DMG MORI DMU-50s are rated at 18,000 RPM (10,000 RPM standard), have coolant through the spindle and are equipped with accurate and easy-to-use probing systems and laser tool setters. XYZ travels are 19.7" x 17.7" x 15.7". "Because of their robust construction, they are well suited for not only small, delicate tight tolerance work, but aggressive machining of harder and heavier materials as well," said Anderson. "It is a 'best of both worlds' situation."

Typical component material machined by C & H includes a variety of aluminum, steels, copper and titanium. According to Anderson, the components manufactured in the 5-axis department are as diverse as they are complicated. "This department, or cell as we like to refer to it, consists of two DMG MORI 5-axis machines and one 3-axis vertical mill," he said. "We make everything from copper transfer manifolds, to aluminum communication components, to landing gear tie rod ends. Ninety-five percent of what we machine on the DMU-50s is started in one 5-axis operation and finished in another 3-axis operation. By flowing parts through this cell, our average start to finish time is cut in half."

Set-up time is another point of savings. According to Bamber, "I cannot put enough emphasis on how beneficial it is having a touch probe and laser tool setter. These devices take set-up times and turn them from hours into minutes. On these DMG MORI machines, we do not have to place the parts perfectly in the center of the C-axis table rotation, or in the exact position of the previous part. No matter where the part is on the table, once the machine probes the part, it knows where it is. The machine then adjusts the work preset accordingly. After that the onboard machine kinematics automatically figure out all 5-axis movements seamlessly and accurately."

"When you consider that the DMU-50s hold up to 60 tools and that you can keep multiple jobs tooled up on one machine at any given time, that is when you really start to unlock the true value of flowing families of parts through a 5-axis cell," said Anderson. "Imagine our savings when we switched our Radio Frequency Housing project from the seven-operation job in a 3-axis cell to a two-operation job in the 5-axis. Once we had proved it out, the next time we did that repeat job we still had the same tooling in the machine and we were able to go from what used to be a 3-axis, 14 hour set-up to cutting parts in less than 30 minutes in the 5-axis. Now for a short run of those parts we can be done with the parts in less time than it used to take to set up - and that also includes better quality."

Last but not least is 5-axis quality. "When you remove the human error of many different operations and set-ups, quality and consistency skyrocket," said Anderson. "Parts with difficult callouts and tolerances become simple to manufacture when you create them in a robust 5-axis environment."

C & H Machine is AS9100:2009 Rev C and ISO 9001:2008 certified and has special process NADCAP certification.

Additional capabilities include a DMG MORI NLX2500SY/700 Turn Mill, which allows efficient machining of multiple operations in minimal set-ups. Other significant machining centers include an Okuma MB5000HA horizontal, a Kitamura HX400 horizontal and a Mikron HSM 400 vertical with an 8-pallet system. The company also utilizes high-speed spindles at over 40,000 RPM and high-pressure coolant. The EDM department has a large AgieCharmilles 640CC with 20" height capacity, as well as a row of FANUC RoboCut wire EDMs with a rotary indexer that can machine with wire as small as .002" diameter.

C & H Machine has a diverse customer base and provides full-service "one-stop shop" capabilities. In addition to milling, turning and EDM, the company provides welding capabilities as well as other special processes.

C & H Machine was founded in 1964 by Carl Warmelin. Charles Gohlich started his career in 1967, learning the trade working for Carl Warmelin who later would become Gohlich's father-in-law. By 1971, Gohlich had earned his Journeyman's Certificate from Mira Costa College and he soon became Production Superintendent.

Lyle Anderson earned a Business Administration degree from Southern Utah and helped manage his family's agricultural business, Lee Anderson's COVALDA Date Company, for five years. Anderson joined C & H Machine in 1981. Gohlich and Anderson took over the business ownership in 1985 and have participated in the transition into the modern era of contract machining.

For more information contact:

Lyle Anderson, President

Geoff Bamber, 5-Axis Machinist

C & H Machine and EDM Services

939 S. Andreasen Dr.

Escondido, CA 92029

760-746-9459

lylea@c-hmachine.com

gbamber@c-hmachine.com

www.c-hmachine.com

Southwest

TX, LA

DMG MORI

Ellison Technologies - Dallas

9001 Currency Street #200

Irving, TX 75063

972-812-5500

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Houston

3403 N. Sam Houston Pkwy. West #100

Houston, TX 77086

713-365-9500

www.ellisontechnologies.com

Southeast

VA, NC, SC

DMG MORI

Ellison Technologies

4345 Morris Park Drive

Charlotte, NC 28227

704-545-7362

www.ellisontechnologies.com

S. AL, GA, MS, TN

DMG MORI

Ellison Technologies

7118 Crossroads Blvd.

Brentwood, TN 37027

615-661-6800

www.ellisontechnologies.com

Northeast

MD, DE

DMG MORI

Ellison Technologies

4345 Morris Park Drive

Charlotte, NC 28227

410-215-1596

Midwest

DMG MORI

Ellison Technologies - Chicago

4630 Weaver Parkway

Warrenville, IL 60555

630-393-8900

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Cincinnati

5333 Mulhauser Road

Hamilton, OH 45011

513-874-2736

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Cleveland

6955 Treeline Drive

Brecksville, OH 44141

440-546-1920

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Davenport

145 West 76th Street

Davenport, IA 52806

563-388-0800

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - St. Louis

16 MB Corporate Park

St. Charles, MO 63301

636-946-7077

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Detroit

29050 Cabot Drive

Novi, MI 48377

248-324-1928

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Grand Rapids

1550 Gezon Parkway SW, Suite B

Wyoming, MI 49509

616-261-8665

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Indianapolis

8930 Bash Road, Suite A

Indianapolis, IN 46256

317-577-3723

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Milwaukee

N27 W23750 Paul Road

Pewaukee, WI 53072

262-523-3400

www.ellisontechnologies.com

DMG MORI

Ellison Technologies - Minneapolis

13400 10th Avenue North

Plymouth, MN 55441

763-545-9699

www.ellisontechnologies.com

West

Southern CA

DMG MORI

Ellison Technologies - Los Angeles

9890 Pioneer Blvd.

Santa Fe Springs, CA 90670

562-949-8311

www.ellisontechnologies.com

Northern CA

DMG MORI

Ellison Technologies - San Francisco

2607 7th St. Suite C

Berkeley, CA 94710

866-814-7238

www.ellisontechnologies.com

WA, ID, MT

DMG MORI

Ellison Technologies - Seattle

19625 62nd Ave. South, Suite A109

Kent, WA 98032

253-872-1661

www.ellisontechnologies.com

OR

DMG MORI

Ellison Technologies - Portland

10159 SW Commerce Circle #K

Wilsonville, OR 97070

503-682-3280

www.ellisontechnologies.com

AZ

DMG MORI

Ellison Machinery Company

1610 S. Priest Dr. #101

Tempe, AZ 85281

480-968-5335

www.ellisonaz.com