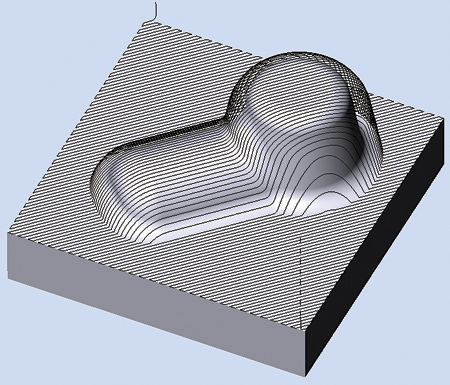

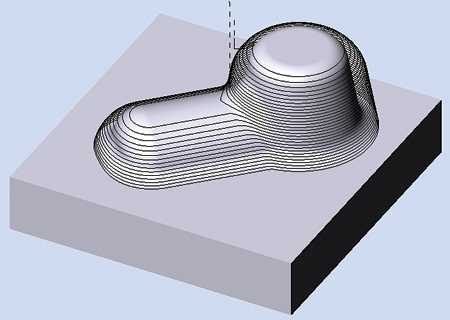

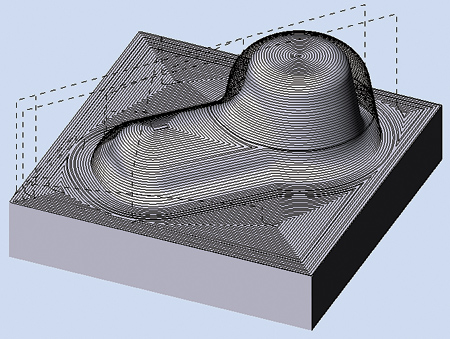

Planar toolpath produces evenly spaced cutting passes projected onto a 3-D model.

Parallel finishing works well on flat or shallow surfaces but causes a problem with scallops when the surface normal is close to that of the parallel intersecting planes.

ESPRIT's Parallel Planes Finishing can improve machining on walls by applying a perpendicular toolpath, rather than parallel, to steep zones.

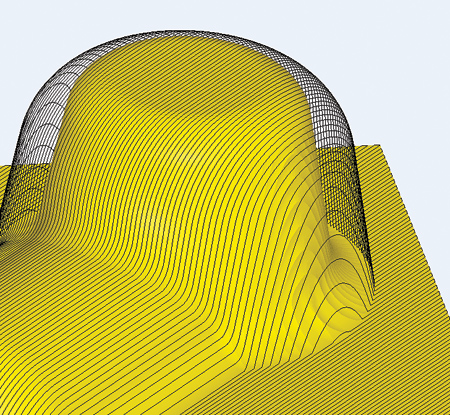

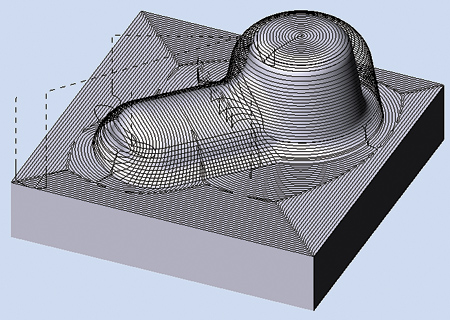

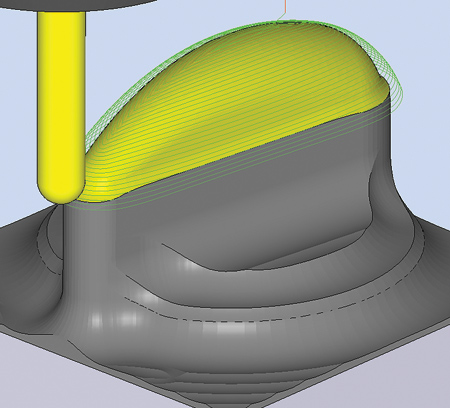

Z-level toolpath produces a good finish on steep regions, since the tool moves progressively downward along the tool axis.

Z-level toolpath works well on steep areas but skips areas where the surface normal is close to that of the intersection planes.

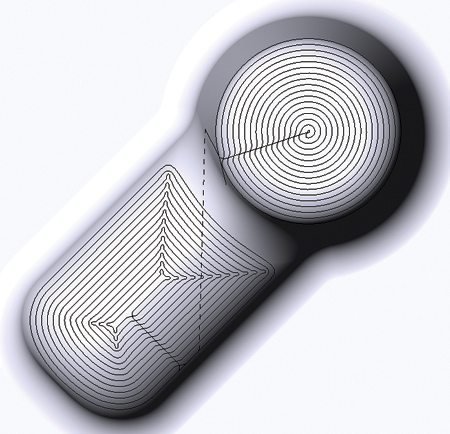

Offset toolpath more closely matches the contours of surfaces.

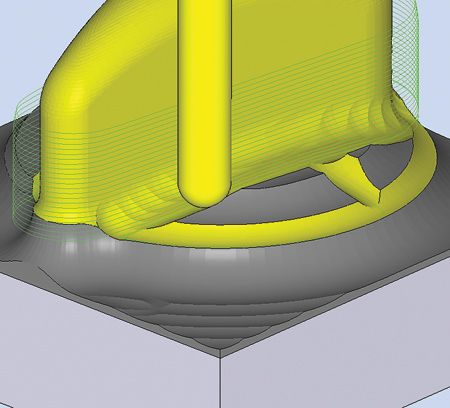

When working with differently shaped boundaries, ESPRIT adapts or "morphs" offset toolpath to compensate for differing outer and inner boundaries.

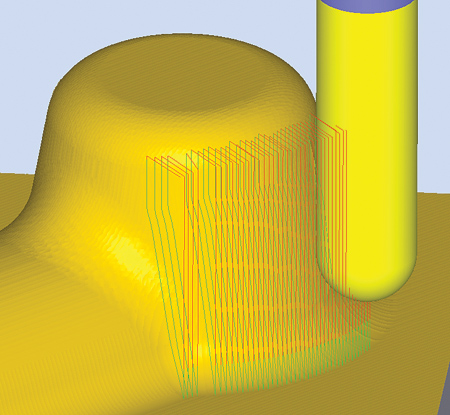

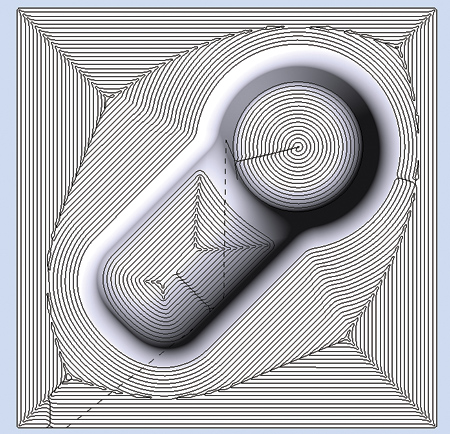

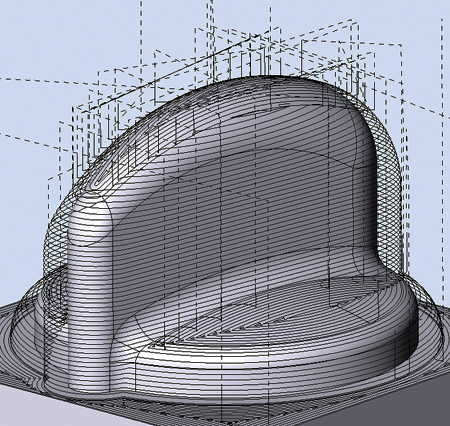

Multiple toolpaths on a single solid model each use the same threshold angle of 60°. Anything below 60° is machined with offset; anything steeper is Z-level.

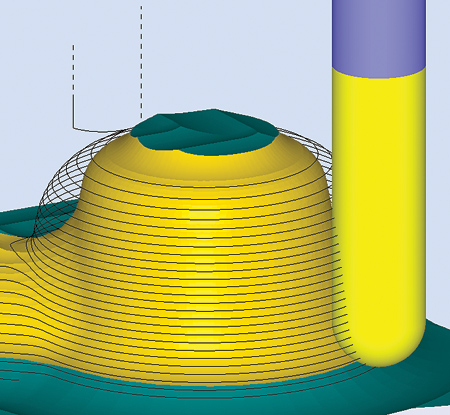

ESPRIT Global Finishing uses a single threshold angle to analyze the shape of complex surfaces to intelligently apply the most appropriate toolpath to machine an entire part.

The toolpath at the top of this model transitions almost imperceptibly from offset cutting passes to Z-level toolpath as the tool moves down the walls. The tool never leaves the surface.

Again, as the tool reaches a shallow zone, the toolpath transitions fluidly back to offset toolpath without retracting the tool.

To achieve the same results with combination finishing requires the creation of multiple separate operations, which result in multiple repositioning moves of the tool.

Smoothing the Ups and Downs of Surface Machining

Freeform surface machining is widely used across many industries to produce sculptured surfaces, generally using multi-axis CNC machining centers. Industries like aerospace, automotive, die and mold, optics and energy utilize advanced computer aided manufacturing (CAM) systems to compute a toolpath that flows across multiple surfaces.

Owing to this high level of machining complexity, the technology in a CAM system must utilize both surface shape and special algorithms to recognize unique surface characteristics like curvature, normal vectors, and convex and concave regions. Depending upon the level of complexity, a toolpath for surface finishing might be applied to the entire surface of the part or by sequentially selecting limiting contours.

To meet modern demands for productivity and surface quality, DP Technology's ESPRIT CAM provides sophisticated machining strategies to calculate advanced surface toolpaths, simulate the process and ultimately generate NC code to drive CNC machine tools via their control units.

Traditional Finishing Strategies

Toolpath planning is critical to achieving a final part that meets engineering requirements in terms of geometrical shape and surface quality. A machining process can either involve a single machining operation for the whole surface or a series of machining operations subdivided by the contours of the surfaces. However, a machining strategy that produces an excellent finish on shallow or flat areas of a model often produces poor results on steep or vertical areas. For this reason, most CAM systems offer a range of choices for finishing strategies.

Let us examine common types of finishing toolpath for parts that have varying surface angles. Freeform surfaces are most often machined with three different toolpath generation methods. These methods traditionally include planar, Z-level and offset.

- Planar Toolpath: In this process, toolpath generation is done by intersection of surfaces with evenly spaced planes in Cartesian space. This method of machining is like a 2-D zig-zag pocket toolpath, except that the toolpath is projected down along the tool axis onto a 3-D part.

While this method is both simple and robust, a drawback becomes immediately apparent when the normal vector of a surface is close to that of the parallel intersecting planes. As the slope of a surface increases, the constant distance between passes can produce large scallops of material on near-vertical walls.

Decreasing the distance between the intersection planes can reduce the scallops on walls but leads to redundant machining of flatter zones. Therefore, applying a single planar strategy to an entire model almost always leads to either excessive machining time or a substandard finish quality.

To address this problem, CAM systems often offer an adaptive planar method that partitions surfaces into different regions according to their slope.

The Parallel Planes Finishing cycle in ESPRIT includes a strategy that lets the programmer partition and exclude zones above a specified slope angle. These "lateral" walls are avoided in the initial machining, and then only those walls can be machined with planar toolpath that is kept perpendicular, rather than parallel.

- Z-Level Toolpath: Z-level toolpath is also planar, except the model is sliced with evenly spaced horizontal planes. In this process, a trace of the model is generated at each level. As with planar toolpath, when a near-horizontal surface has a normal vector that is close to that of the intersection plane, surface quality suffers.

- Offset Toolpath: Another technique that works well on shallow or flat regions uses the shape that bounds the region to define the shape of the toolpath. The CAM system uses a slope threshold to identify and partition steep and shallow regions, and then the toolpath is generated by offsetting the boundary of each region by a constant distance.

- Combination Finishing: When a complex model has many areas of steep walls and shallow floors, applying a single machining strategy to the entire model often leads to excessive machining time that only results in a substandard finish. Producing an acceptable finish on the model, then, involves the extra work of identifying the boundaries between steep/shallow zones and applying separate strategies that can lead to "waterline" marks along those boundaries since the tool must transition to machine each zone individually.

ESPRIT efficiently controls the machining of steep/shallow surface topology without the need for steep/shallow boundaries. This means that the CAM system can analyze surface angles of a model at runtime to identify and partition machining zones based on slope angle.

When a CNC programmer chooses a combination of toolpaths to cut a 3-D model, some of the problems with this approach are:

- Multiple toolpaths require multiple retract moves, with the tool constantly being repositioned from one area to another. The more surfaces on the part, the more retract moves there are as the tool moves from one style of toolpath to another. No matter how accurate the machine, these moves are bound to leave a mark due to tool wear, deflection and the locations of previous toolpaths.

- Multiple toolpaths take more time to plan, test and machine, and can result in an inconsistent surface finish across the entire part. Some toolpaths may produce a better finish on certain areas than toolpaths in other areas, requiring the programmer to continuously adjust the machining parameters for each toolpath.

- Depending on the machining criteria specified for the toolpath and the CAM system, some areas of the model might be machined multiple times when multiple toolpaths overlap.

CAM systems that have intelligent machining capabilities solve these problems with a sophisticated type of toolpath that intelligently applies the appropriate combination of Z-level and projection cutting passes based on the shape of the 3-D model.

Global Finishing as a Comprehensive Solution

ESPRIT features a 3-axis Global Finishing method that combines the best of Z-level finishing and offset finishing in one comprehensive solution for steep/shallow milling.

Global Finishing optimizes machining by not only calculating the most appropriate toolpath for steep and shallow zones, but also by applying fluid transitions between zones to keep the cutter in continuous motion, thus eliminating visible marks between zones and improving machine utilization.

Advantages of using a single, global solution include:

- A single operation with a single threshold angle requires less time to program and less guesswork. ESPRIT uses the threshold angle to identify and partition regions by surface angle and then apply automatically Z-level cutting passes to steep areas and offset passes to shallow areas.

- The Global Finishing interface is streamlined to present only key parameters, such as tolerance and step over, for faster programming. Climb milling and spiral connections are enabled by default for smoother finishing.

- Sophisticated logic gives priority to continuity of toolpath as surfaces transition from flat to vertical, and attempts to preserve uninterrupted Z-level passes as much as possible. The system first calculates Z-level toolpath on the entire part. All toolpath that flows entirely on areas above the slope threshold is maintained. Toolpath in areas below the slope threshold is replaced with offset passes.

Looking Ahead

The first implementation of Global Finishing keeps options to a minimum to optimize programming time and minimize cycle time. Faster, smarter programming is accomplished through a simplified user interface and an emphasis on automated application of Z-level and offset cutting passes, with continuity of toolpath taking priority.

Future development plans for Global Finishing will offer CNC programmers a choice of patterns for horizontal areas - parallel or offset. Extra options are also planned that will let the programmer choose a priority for time versus surface quality. For example, optimization of cycle time could be prioritized for foam samples or parts with less complexity, while a higher priority could be placed on optimum surface quality for parts with high complexity.

Global Finishing will continue to evolve as a comprehensive solution for sculptured surface machining through the continuous development of sophisticated CAM logic based on customer feedback and strenuous lab testing.

A technical overview authored by DP Technology

For more information contact:

Richard Allen

Corporate Marketing &

Communications Director

DP Technology

1150 Avenida Acaso

Camarillo, CA 93012

805-388-6000

richard.allen@dptechnology.com

www.dptechnology.com

www.espritcam.com