New GARANT PPC solid carbide barrel milling cutters and GARANT precision copy milling cutters with new PPC indexable insert enable finishing of components made from high-alloy and hardened steels.

GARANT PPC indexable inserts finish flat faces and freely accessible surfaces without interference contours and are optimized for steel, stainless steel, high-alloy and hardened steels and aluminum.

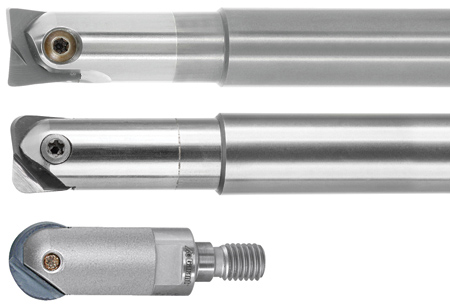

GARANT PPC indexable inserts are compatible with GARANT precision copy milling cutters made from steel or solid carbide as tool bodies.

Hoffmann Group USA has expanded its tool family for Parabolic Performance Cutting (PPC) to include a new PPC indexable insert and GARANT PPC solid carbide barrel milling cutters for high-alloy and hardened steels. The PPC process represents a further development of ball-nosed slot drill cutting and is also known as barrel milling. It is primarily used for finishing free-form surfaces in machining tool building, tool making and die making and is designed to achieve either up to nine times shorter processing times or a significantly improved surface quality.

With its new PPC indexable insert, which is compatible with the GARANT precision copy milling cutters as tool bodies, the Hoffmann Group is launching an alternative to PPC solid carbide barrel milling cutters with a straight or stub point conical-shaped main cutting edge to the market. The PPC cut-off inserts are suitable for processing flat faces and freely accessible surfaces without interference contours on a 3-axis machine and are available for steel, high-alloy and hardened steels, stainless steel and aluminum. GARANT precision copy milling cutters, which are suitable as tool bodies, are available in steel and solid carbide versions, including a GARANT PowerCard.

In addition to the new PPC indexable insert, the Hoffmann Group has optimized three versions of its PPC solid carbide barrel milling cutter for hard machining. The new tools have a tangential, conical or stub point conical form and are suitable for finishing flat faces and large surfaces with interference contours, as well as deep and hard-to-access cavities. Due to these qualities, they show their full potential on the 5-axis machine. The new GARANT PPC indexable milling inserts are also available to users for finishing components made from high-alloy or hardened steels with freely accessible surfaces without interference contours.

All new GARANT PPC indexable inserts, including tool bodies and the new GARANT PPC solid carbide barrel milling cutters for hard machining, are available immediately via the e-shop from the Hoffmann Group and from the 2019/2020 catalogue. The precondition for PPC is a CAD/CAM software coordinated to the milling strategy which allows the tool geometries to be processed as a data model.

For more information contact:

Hoffmann Group USA

202 N. Seven Oaks Drive

Knoxville, TN 37922

844-448-7725

sales.usa@hoffmann-group.com

www.hoffmann-group.com