ESAB's new water-cooled MIG guns, the 7W, 9W and MXH 420W PP, are designed to keep the operator more comfortable and promote longer consumables life in heat-heat applications.

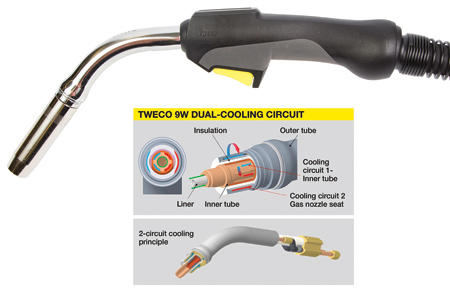

The Tweco 9W MIG gun features a dual-circuit cooling system that brings cooling water all the way to the seat of the gas nozzle, as well as to the conductor tube.

The new Tweco series of water-cooled MIG guns features an advanced ergonomic design with rubberized soft-grip areas to help avoid hand fatigue.

Tweco, an ESAB brand, has launched its Tweco Fusion Pro 7W and 9W water-cooled MIG guns for high-amperage welding with solid and cored wires and the Tweco MXH 420W PP (push-pull) water-cooled gun for MIG aluminum and longer reach applications.

"These water-cooled guns represent a new series of Tweco high-performance guns that offer superior comfort, ergonomics and lower total cost of operation," said John Esposito, Global Product Manager, ESAB Welding & Cutting Products. "Water-cooled guns weigh an average of 38% less than comparably-rated air-cooled guns. Coupled with advanced cooling performance that extends consumables life, these guns promote all-day operator comfort in high-heat applications like pulsed MIG welding and welding with large diameter cored, solid and aluminum wires. They are a win-win for operators and your bottom line."

The Fusion Pro 7W is rated at 450A @ 100% duty cycle with mixed gas, 500A @ 100% duty cycle with CO2. The 9W is rated at 500A @ 100% duty cycle with mixed gas, 550A @ 100% duty cycle with CO2. The 9W features a dual-circuit cooling system that brings cooling water all the way to the seat of the gas nozzle, as well as to the conductor tube. The guns are available with 10', 12' and 15' cable lengths, and the back-end can be configured for Tweco-style, Euro-style and competitive wire feeder connections.

The Fusion Pro 7W and 9W feature an advanced ergonomic design with rubberized soft-grip areas to promote a sure grip while helping avoid hand fatigue. In addition, knuckle joints and spring supports at the gun/cable transition point improve flexibility to reduce wrist strain. Both guns feature Tweco's new M series threaded contact tips that are available in pure copper (Ecu) or a premium CuCrZr alloy that resists wear so operators can weld longer on a single tip.

"These guns stay cooler and feel more comfortable. Operators will experience a noticeable advantage between Tweco and competitive guns," said Esposito.

The MXH 420W PP, rated at 400A @ 100% duty cycle with mixed gas, is designed to provide consistent wire feeding performances over long distances and for challenging situations with soft and smaller diameter wires at wire feed speeds up to 26.5 FPS. This push-pull gun offers plug & play performance with any ESAB 3004 feeder system (Aristo, Origo or Warrior Feed) by using the MXH adapter.

The MXH features a comfortable pistol grip and well-balanced design. "The operator can manipulate the gun with less fatigue, as well as adjust wire feed speed at the gun for more control," said a company spokesperson. "The simple feed rolls are easily replaced, and the strong feeding mechanism provides positive performance with the 20 ft. and 33 ft. cable length options. The MXH uses PSF wear parts that also include long-lasting contact tips made from a CuCrZr alloy."

"While water-cooled guns require a higher initial expense, their enhanced cooling capabilities provide a better payback," said Esposito. "To start, consumables last about twice as long compared to an air-cooled gun, and that also means half the amount of downtime related to consumable changes. Next, a cooler-running gun reduces or eliminates the `stick-slip' phenomena that occurs when components overheat and seize the wire, which is evidenced by erratic feeding performance. A more stable arc also lowers spatter, and spatter doesn't adhere as readily, so there is less need to clean the nozzle and less risk of shielding gas turbulence."

For more information contact:

ESAB Welding & Cutting Products

800-ESAB-123 / 864-466-0921

www.esabna.com