The Marposs NVH Gear Tester identifies potential gear defects at the component level that can lead to transmission noise.

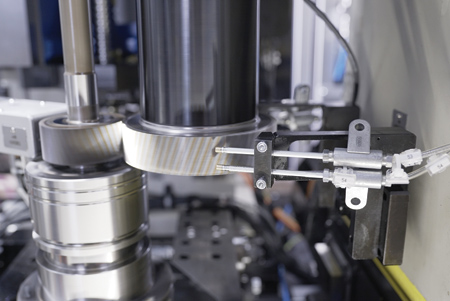

Marposs' NVH Gear Tester is designed for identifying potential gear defects at the component level prior to gear box assembly. The NVH gear tester, which works on the Single Flank testing principle of one master gear meshing with the component under inspection, is able to detect macro-geometry (nicks, runout, etc.) and micro-geometry (gear mesh excitation, ghost orders) defects that cause gear whine and noise phenomena.

With electrification of the automotive industry, many hybrid (HEV) and full electric vehicles (EV) drivetrains are facing many challenges, such as increased NVH requirements in high-speed e-Drives. And, although the number of gear wheels is significantly reduced in electric vehicles due to the use of one- or two-speed reducers instead of the classic manual, automatic or twin-clutch gearboxes, these gear wheels are loaded with torque and RPM not previously found in high-volume production.

With hybrids and EVs, the noise from an internal combustion engine (ICE) is intermittent or nonexistent, so that transmission makes the most dominant vehicle noise. Noise, therefore, becomes not only a mechanical issue for the performance of the transmission, but also a comfort issue for the driver.

Basically, the concept of NVH testing is to stress the gears by applying rotation speeds and torque values similar (or even higher) to those that are applied in the real working conditions. The ability to test gears at operating conditions almost comparable to the final e-Drive is a main benefit of the NVH Gear Tester.

The output parameter is the angular acceleration of the part (or master), evaluated instantaneously and in the long run with the use of encoders (TE inspection) and torsional accelerometer (TAC inspection). The stiff granite structure of the NVH gear tester makes it impervious to external interferences and a highly configurable software make this system as good as correlating data with the End of Line test rig.

The NVH gear tester has a maximum rotating speed of 3,000 RPM, driving torque of 0 Nm to 30 Nm and can accommodate a maximum gear tooth height of 70 mm and shaft length of 280 mm. It can be designed to work with either manual or automatic loading.

For more information contact:

Marposs Corporation

3300 Cross Creek Parkway

Auburn Hills, MI 48326

248-370-0404

marposs@us.marposs.com

www.marposs.com/eng/application/

nvh-machine-for-gears