The large front-open work area enables easy set-up.

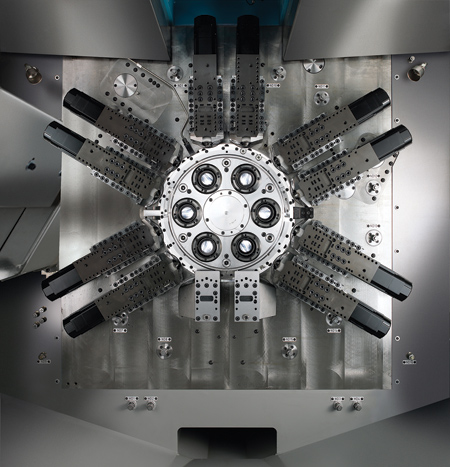

INDEX CNC multi-spindle machines can be configured according to customer requirements in terms of the number of cross-slides, Y axes and synchronous spindles.

Different tools for different machining operations per spindle position can be installed on the cross-slides.

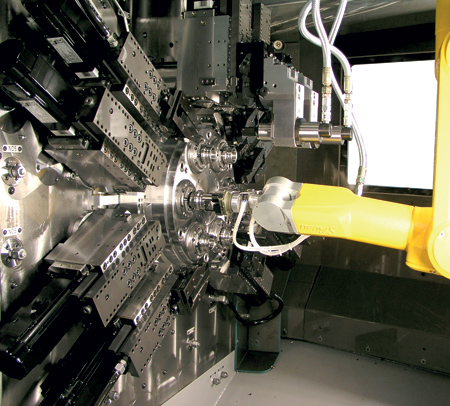

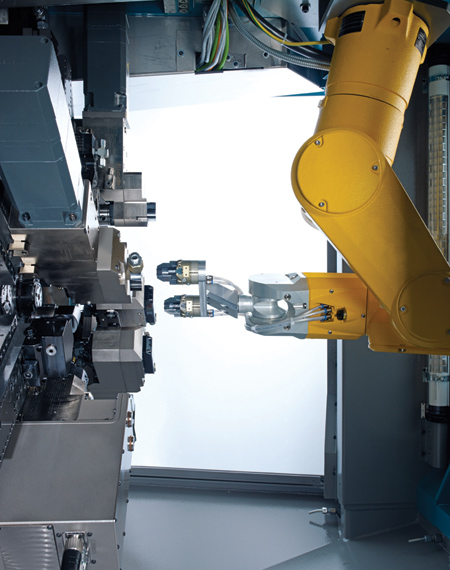

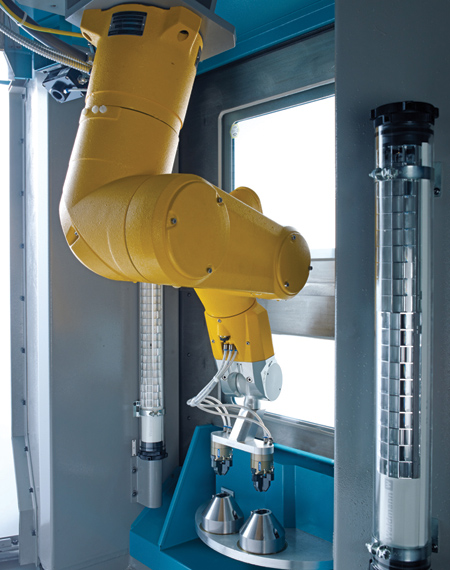

Robot handling for machining of chucked parts

Depositing the workpiece on the swivel disk: transfer to the peripheral handling interface

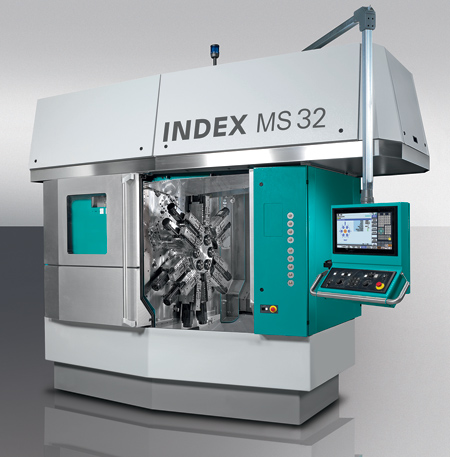

The INDEX MS32C2 multi-spindle lathe and its custom configuration with up to 12 CNC cross-slides, Y-axes, a synchronous spindle and other options allow highly efficient production of bar and chucked parts.

Chucked parts can be machined up to a blank diameter of approximately 60 mm. The INDEX machine features a tool carrier arrangement in the work area without a longitudinal sliding block, which allows more than one tool to be used on each spindle. The generously dimensioned work area can be optimally accessed through two sliding doors on the side.

An advantageous slide arrangement provides unhindered chip flow and improved process reliability. The core of the machine is the compact spindle drum with six fluid-cooled motor spindles in synchronous design. Additional characteristics of the machine include infinitely variable speed control, high torque, small frame size and maintenance-free operation.

The INDEX modular system allows customer-specific configuration of up to 12 hydrostatic bearing-supported CNC cross-slides, Y-axes, a synchronous spindle and numerous stationary and live tools for machining the front and rear ends of workpieces. The front-open machine concept and the V-shaped arrangement of the tool carriers help ensure that the optimum technological sequence alone determines the machining method. Thus, for example, external and internal machining operations using stationary or live tools can be carried out in every station.

"The familiar proven advantages of the INDEX CNC multi-spindle machines, such as the use of hollow-shaft motor technology in all work spindles and the optimum selection of cutting data via the CNC program, were carried over into the development of the MS32C2," said a company spokesperson. During machining, it is always possible to program the optimum speed, which can still be varied during cutting, for each spindle position and each cutting edge of the tool. "The result is optimum chipping, maximum surface quality, short production times per piece and extended tool life," said the spokesperson. "Users can also machine troublesome materials that up to now were hardly suitable for multi-spindle machines. It is also possible to make speed changes during drum indexing, thus avoiding any additional secondary processing times. The C-axes available in all spindle positions also permit complete machining of intricate workpieces in minimum time. The optionally available Y-axes expand the range of machinable workpieces even more."

To machine chucked parts, the MS32C2 may be used for automatic loading due to its generous work area without a longitudinal slide block. The optionally built-in robot with a single, double or quadruple gripper in the work area handles the loading and unloading of workpieces. The 110 mm chuck allows machining of pre-formed, forged or extruded parts up to approximately 60 mm.

A main advantage of the INDEX MS32C2 is its flexibility. The machine allows configuration of various tools on the cross-slides and, thus, integration of numerous machining technologies: off-center drilling, thread cutting, inclined drilling, cross drilling, contour milling, hobbing, multi-edge turning and more. "The MS32C2 delivers impressive cost effectiveness not just for medium and large batch sizes; for component families, in particular, it plays to its strengths with its ease of re-equipping," said the spokesperson.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

www.indextraub.com

Southwest

N. TX

Hillary Machinery, Inc.

1825 Summit, #207

Plano, TX 75074

972-578-1515

www.hillaryinc.com

S. TX

PD Browne South

440 Brenmar

Houston, TX 77060

281-405-9378

www.pdbrownesouth.com

OK

Gage Machine Tool

10668 Widmer Road

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

Southeast

AL, GA

Applied Machine Solutions, Inc.

2200 Airport Industrial Dr., Suite 300

Ball Ground, GA 30107

678-880-0893

info@appliedmachine.com

www.appliedmachine.com

NC, SC, VA

Advance Machinery Sales, Inc.

416-C Gallimore Dairy Rd.

Greensboro, NC 27409

336-665-9114

www.am-sales.com

FL

Arthur Machinery

5903 Johns Rd.

Tampa, FL 33634

813-887-4455

www.arthurmachinery.com

Northeast

DE, MD, E. PA, NJ, NYC, Long Island

Automation Solutions, Inc.

2 Hagerty Blvd., Ste. 300

West Chester, PA 19382

610-430-3670

inquire@asi-pa.com

www.asi-pa.com

N. NY

Britton Machinery Sales

P.O. Box 709

Pittsford, NY 14534

585-924-9335

www.brittonmachinery.com

W. PA

Marcus Machinery

106 Bellefield Court

Gibsonia, PA 15044

412-862-0803

info@marcusmachinery.com

www.marcusmachinery.com

MA, CT, RI, ME, NH, VT

Northeast CNC, LLC

36 Bartlett Rd., Unit 1

Gorham, ME 04038

207-775-5510

sales@necnc.com

www.necnc.com

Midwest

KS, W. MO

Gage Machine Tool

10668 Widmer Rd.

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

E. WI

Iverson & Company

441 North 3rd Ave.

Des Plaines, IL 60016

847-299-2461

sales@iversonandco.com

www.iversonandco.com

MI

Methods & Equipment Associates

31731 Glendale Ave.

Livonia, MI 48150

734-293-0660

sales@methods-equipment.com

www.methods-equipment.com

MN, IA, ND, SD, E. NE, W. WI

Hales Machine Tool, Inc.

2730 Niagara Lane North

Plymouth, MN 55447

763-553-1711

sales@halesmachinetool.com

www.halesmachinetool.com

West

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street E.

Fife, WA 98424

253-926-6868

sales@ellismachinery.com

www.ellismachinery.com