Repurposed CMMs with Laser Scanning, Easy-to-Use Software

March 1, 2016

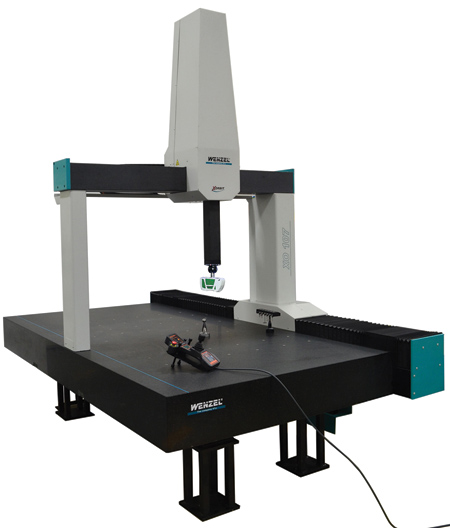

Newly repurposed Wenzel CMM with TouchDMIS and Perceptron ScanR laser scanner added.

Following the launch of its sixth generation ScanR series of laser scanning sensors, Perceptron has begun remanufacturing coordinate measuring machines (CMMs) for resale. The Perceptron repurposed CMMs will include new CNC controller and electronics, TouchDMIS measuring software and a Perceptron ScanR laser scanner, seamlessly integrated with its TouchCloud software module, to offer full point-cloud creation with automatic feature extraction. "The use of laser scanners on manual CMMs has increased dramatically over the past several years, and now this technology is available with higher accuracy than traditional portal CNC CMMs," said a company spokesperson.

Jeff Armstrong, President of Perceptron, said, "Since the acquisition of the COORD3 CMM business, we have begun to offer our ScanR scanners on all of our new CMMs as a fully-integrated solution. Incorporating our ScanR and TouchDMIS software on a repurposed CMM is a natural extension of our strategy to offer upgrades to the 100,000+ CMMs and PCMMs already in service around the world. This offers a low cost opportunity for owners to extend equipment life, reduce inspection time and costs, and significantly improve functionality by adding the ability to scan an existing part to create a CAD model or directly reproduce it on a 3-D printer."

The ScanR CMM laser scanners are mounted directly to the Renishaw probe head and provide for multi-sensor hybrid CMM capability, allowing both repetitive automatic part inspection and reverse engineering. The repurposed CMM program allows a pre-owned touch probe CMM to be factory refurbished and updated with the latest scanning sensor and easy-to-operate touch software.

Perceptron repurposed CMMs come standard with the Red Laser ScanR. They can be upgraded to the ScanR Performance model offering a green laser with the ability to scan highly reflective parts, extending the range of engineering materials that can be laser-scanned without part spraying.

For more information contact:

Perceptron, Inc.

47827 Halyard Drive

Plymouth, MI 48170

734-414-6100

info@perceptron.com

www.perceptron.com

< back