The new Affolter AF110 plus and the WSPS technology will open completely new opportunities for American customers. (Picture source: Affolter Technologies SA)

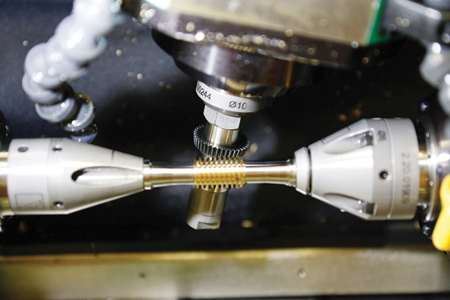

Boosting the productivity: Affolter's Worm Screw Power Skiving (WSPS) technology is four times faster than the traditional worm hobbing. (Picture source: Affolter Technologies SA)

Affolter Technologies will showcase the new gear hobbing center Affolter AF110 plus, designed to maximize productivity for manufacturing small gears in the automotive, aerospace and medical equipment industries.

"It is the most advanced machine offered by Affolter Technologies, the Swiss technology and market leader of small gear hobbing systems," said a company spokesperson.

The AF110 plus has eight axes with a maximum DP17, minimal DP1270 and a spindle speed of up to 12,000 RPM. Different automation systems for part loading and unloading are available, such as universal grippers, drum loader or robot loading as well as options such as deburring, dry cutting, centering microscope and oil mist aspiration.

The new loader system AF71 with two grippers provides 24 hours automatic production. While a gear is in the hobbing process, the other gripper already reaches out for the next part to load. The AF110 plus can cut spur, helical, frontal, bevel and crown gears. The machine is equipped with the in-house developed Affolter Leste CNC control, specifically designed for handling up to 12 axes. The newly designed worm screw power skiving (WSPS) technology is available as an option. The Affolter AF110 plus is designed to be fast, ergonomic and environmentally friendly.

"It is an innovative machine concept: power, rigidity and precision combined with universal applicability provide a means of manufacturing complex parts at the cutting edge of technology. From standard products to custom-made developments, it encompasses the full range of expertise in very stringent fields," said Mikael Affolter, Head of Sales, Affolter Technologies.

WSPS for Optimized Productivity

"The idea behind the recently introduced WSPS technology is, unlike in worm hobbing, where the hob turns much faster than the workpiece, the Affolter engineers inverted the process. The workpiece turns extremely fast, with two new spindles up to 12,000 RPM, while the cutter turns much slower. Only technologically advanced machines can reach such speeds and at the same time provide the necessary stiffness," said Managing Director Vincent Affolter.

Affolter sees a large demand for this WSPS technology in the automotive, aerospace and medical equipment industries. "WSPS allows us to finish a high-precision worm in only six seconds. If done by worm hobbing, every piece takes about 25 seconds," continued Affolter. "In other words, WSPS reduces cycle time by up to four times." Manufacturers of high volume worms in these industries will benefit from this new process. The WSPS technology focuses on small worms with a module up to 17 DP.

Affolter is represented in North America by Rotec Tools Ltd., which offers sales, service and parts support.

"Affolter offers great machines for customers that are already making gears or customers that are considering making gears," said Ivo Straessle, President of Rotec Tools. "The simplicity of these machines is remarkable. The user-friendly controls with step-by-step and easy-to-follow functions will simplify the gear-making process."

For more information contact:

Affolter Technologies

www.affoltergroup.ch

www.affolter-applications.ch

Gear Expo Booth 537

Rotec Tools Ltd.

100 Buckshollow Rd. Unit 3

Lemcar Industrial Park

Mahopac, NY 10541

845-621-9100

info@rotectools.com

www.rotectools.com