New 3-D Roughing strategy with step optimization

hyperCAD-S Electrode, a new design module for fast, easy programming of electrodes

A new positioning function for convenient fixturing in hyperCAD-S

OPEN MIND Technologies AG, a developer of CAM software solutions worldwide, has introduced hyperMILL 2017.2, the company's newest release of the hyperMILL CAM suite. "OPEN MIND has further enhanced hyperMILL, one of the industry's most advanced, comprehensive CAM software, providing users a broad array of features designed to improve their manufacturing process with unmatched speed and flexibility," said a company spokesperson. "Improved machining strategies, 3-D milling and programming aids such as T-slot recognition, and an entirely new module for the production of die-sinking electrodes are several examples of hyperMILL 2017.2."

Alan Levine, Managing Director of OPEN MIND Technologies USA, Inc., said, "With hyperMILL 2017.2, users can now program easier and faster than ever and will appreciate its convenient, time-saving aids, the new powerful electrode module function and the enhancement to swarf milling in hyperMILL for SOLIDWORKS."

hyperMILL 2017.2 highlights include the following:

- 3-D Machining Strategies/ Feature Detection Updates - Using hyperMill 2017.2, fast detection and programming of T-slots is now possible. With just a few clicks, T-slots can be very efficiently produced. Two types of feature recognition are included: T-slots, and pockets with bottom and T-slots.

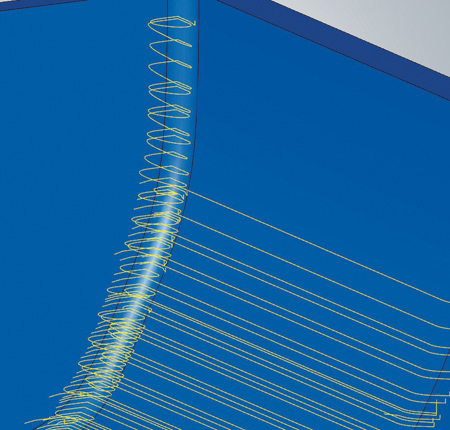

Another key feature of 2017.2 is 3-D Optimized Roughing, a machining enhancement for the roughing of rest material. In addition, to further optimize strategy for stepovers, an option calculates the optimal width in relation to the additional chip thickness and depth value, enabling the user to adjust machining parameters to the condition of the tool. This is especially beneficial for tools with longer cutting lengths that can be precisely controlled using a maximum stepover parameter.

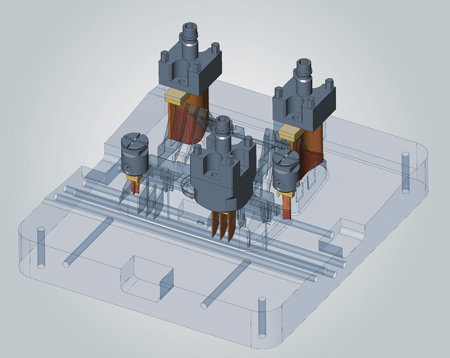

- hyperCAD-S Electrode - A special CAD program developed for the needs of CAM programmers, hyperCAD-S now features an innovative function for the fast design of electrodes. An automated process requiring only a few clicks ensures easy, optimal electrode design from the face of the component geometry to be eroded, and does not require the user to have any special design skills. Once the programmer has selected the faces on the workpiece, hyperCAD-S creates corresponding collision-free electrodes with the necessary surfaces, creating an electrode directly from the model, providing accuracy and integrity of the design. The seamless transfer in hyperMILL is based on geometry and technological data. The CAM system supports the user with its own dialog window and feature type during electrode programming. All of the important data is transferred directly from the hyperCAD-S module and into the feature information, simplifying programming and avoiding errors.

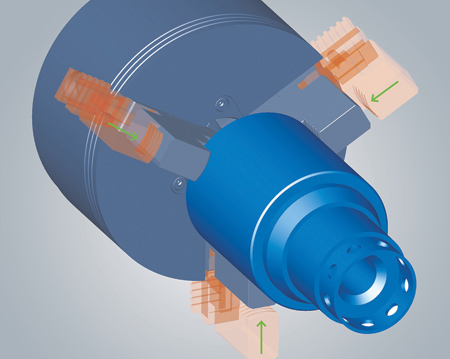

- hyperCAD-S Fixturing Enhancements - Further innovative functions in hyperCAD-S include the positioning of fixturing components, providing the ability to fixture and adjust to match whatever side of the part the user is making. For example, elements such as clamping jaws can be moved linearly or radially to the optimal positioning.

- 5-Axis Swarf Milling with One Curve - Two new fast, easy to program user-friendly functions for hyperMILL for SOLIDWORKS have been added in 2017.2, allowing operators to have an ideal face and curve created automatically for swarf cutting based on selected geometries. With this unique utility, unavailable in SOLIDWORKS alone or any other CAM program, interior corners can be automatically filleted, ensuring optimal machining.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com