The factory of the future is digital: EOS solutions for industrial 3-D printing enable a highly flexible and efficient production

The new EOS software generation - fully integrated in the production workflow

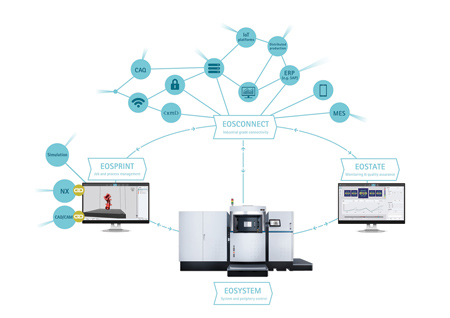

EOS offers its latest versions of EOSPRINT 2 for job and process management, the process monitoring suite EOSTATE, as well as EOSCONNECT that provides industrial grade connectivity. EOS software provides businesses with the necessary tools to fully integrate industrial 3-D printing into their manufacturing process, enabling flexible production and increased efficiency.

Dr. Tobias Abeln, Chief Technical Officer (CTO) at EOS, said, "We understand the challenges of our customers with regards to industry 4.0 and the need for increased productivity. EOS' software solutions support companies across all process steps in additive manufacturing (AM) - from an efficient preparation of the AM build job with EOSPRINT to quality control as part of the EOSTATE monitoring suite. And with EOSCONNECT, all the machine and production data collected can be made usable on a live basis. "To enable this, EOS offers an open interface capable of providing integration either into intelligent EOS applications providing productivity increase or to be used by third party applications. This way we lay the foundation for companies to truly integrate AM in industrial production environments."

EOSPRINT 2 - Job and Process Management

EOSPRINT 2 is an intuitive, open and productive CAM tool that allows businesses to optimize CAD data for EOS systems. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive AM CAM environment for engineers who want to fully leverage the benefits of AM with production-ready design.

With a bundle of new features enhancing productivity such as Z-segmentation and unique exposure patterns, EOSPRINT 2 adds to the integration of AM into serial production. Customers integrating AM and post-process machining can profit from the reference point calibration feature. The feature is essential to set the same zero point across different machine types, such as milling and turning machines and industrial 3-D printing. Additionally, EOSPRINT offers expert functionalities to enhance material and process development with the DoE (Design of Experiments) Set-up feature.

EOSTATE - Process Monitoring Suite

EOSTATE is an automated and intelligent multi monitoring suite that enables customers to conduct a real-time quality assurance of all production and quality relevant data. It is composed of four different monitoring tools: System, PowderBed, MeltPool and Exposure OT (optical tomography).

EOSTATE Exposure OT provides real-time, camera-based monitoring of the additive, metal-based build process. The solution fully maps each part throughout the build process, layer by layer, regardless of its geometry and size. Developed in close collaboration with EOS' strategic partner MTU Aero Engines, EOSTATE Exposure OT enables companies to reduce costs for non-destructive examination in computer tomography after the build process, since potentially defective parts can be rejected at an earlier stage.

EOSTATE MeltPool makes it possible to transparently display the complex melting process. During the build process, the tool measures the light emissions of the melt pool by means of sensors. For this, the process light is separated from the reflected laser light using elaborate hardware. The data thus captured is additionally processed and interpreted by the software system. EOSTATE MeltPool is suitable for users who want to advance their research and process development or optimize their manufacturing methods.

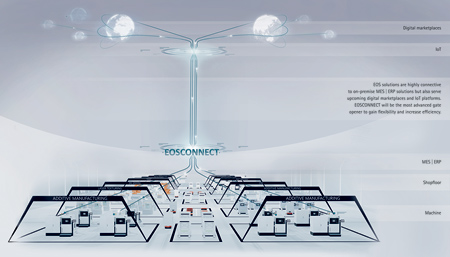

EOSCONNECT - Industrial Grade Connectivity

EOS solutions are highly connective to on premise MES/ERP solutions but also serve upcoming digital marketplaces and IoT platforms. "EOSCONNECT will be the most advanced gate opener to gain flexibility and increase productivity," said a company spokesperson. Machine and production data can be gathered and made available in near real-time. EOS even offers an intuitive app to visualize the data in a dashboard. This is the next step towards a comprehensive and user-friendly machine park surveillance.

This high connectivity enables two beneficial outcomes: companies gain a seamless handover of production data into their systems' Computer Aided Quality (CAQ) for secure traceability, helping them to validate their processes for production. They also can benefit from transparency with visualization and readout of real-time production KPIs. In the end, the connectivity helps businesses to improve their productivity.

For more information contact:

EOS of North America, Inc.

28970 Cabot Drive, Suite 700

Novi, MI 48377-2978

248-306-0143

info@eos-na.com

www.eos.info