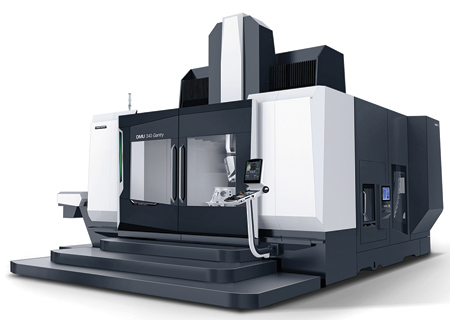

The DMU 340 Gantry, with its 35.3 cubic ft. work area volume, was particularly developed for large component machining in the aerospace industry, tool and mold making and general mechanical engineering.

DMG MORI's DMU 340 Gantry with CELOS was developed especially for large component machining in the aerospace industry, tool and mold making and general mechanical engineering.

The work area of the DMU 340 Gantry measures 133.9" x 110.2" x 49.2" and provides expansion options to up to 236.2" in the X- and 59.1" in the Z-axis. Due to its gantry design, it also has compact dimensions. Direct drives in the B- and C-axis as well as linear drives in the X- and Y-axis enable dynamic 5-axis simultaneous machining of workpieces-primarily made of carbon aluminum, steel and cast iron. A spindle module with speeds up to 30,000 RPM or up to 317.2 ft-lbs. torque support the large range of components. The linear drives in the X- and Y-axis are contact-free, offer long-term precision, are maintenance-free and provide dynamics of up to 5 g.

"Coupled with the rigidity of the machines, this enables excellent surfaces up to Ra 0.3 µ. Furthermore, high rapid traverses result in a significant reduction of the machining time by up to 30%," said Markus Piber, Divisional Board Member Sales and Technology Excellence of DMG MORI Management GmbH. The single-piece, thermo-symmetrical machine bed and comprehensive cooling measures allow high thermal stability, and thus enable complex machining under changing conditions.

The standard version with a 173.2" x 106.3" table accommodates workpieces weighing up to 22,046 lbs. The maximum load can optionally be increased to 66,138.7 lbs. Workpieces measuring up to 173.2" x 119.7" x 60.7" can be machined within the machine's small footprint of 635.1 sq. ft. The B-axis milling head has a 50° swivel plane, enabling the machining of angles up to -10°.

The DMU 340 Gantry uses the SK40 speedMASTER motor spindle as standard, produced in-house with 15,000 RPM and 317.2 ft-lbs. The range of spindle modules allows application-specific equipment. HSK-A63 speedMASTER spindles with up to 30,000 RPM or up to 105.9 HP for high machining performance allow enhanced surface finishes to meet aerospace requirements. The HSK-A100 spindles with 317.2 ft-lbs. torque are suitable for heavy-duty machining, specifically in moldmaking. There is space for 30 tools in the chain magazine as standard. The optional wheel magazine provides space for 63 tools and can be extended to up to 183 tool pockets.

DMG MORI uses CELOS for the DMU 340 Gantry, as it does for all its machines. DMG MORI also presented CELOS on HEIDENHAIN at IMTS 2018. The app-based control and operating interface supports operators with a 21.5" multi-touch display and 27 CELOS apps for the organization of orders and process optimization. CELOS acts as an interface for integration of the machine into the company organization and for interaction in production networks of the future. Adding to this are intelligent equipment options for optimizing manufacturing processes and further increasing process reliability. These include, among others, an infrared measuring probe, tool measurement in the work area, mechanical tool breakage monitoring as well as Machine Protection Control (MPC) for reliable prevention of collisions.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI (364-6674)

www.us.dmgmori.com