When a High Precision Rotary air bearing rotary indexer with 1 arc-second accuracy, and a Feather Probe .005" stylus that can measure holes as small as .009" in diameter are coupled together, a fuel injector can be fully characterized.

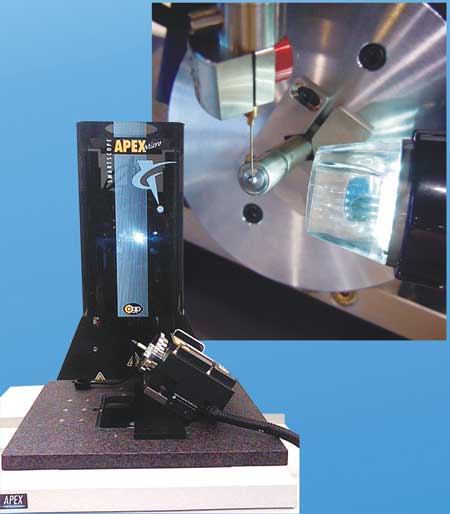

Optical Gaging Products (OGP), a division of Quality Vision International (QVI), offers its SmartScope Apex Micro Metrology System to the micro manufacturing marketplace.

SmartScope Apex Micro is a high-resolution floor model fixed optics metrology system that features a state-of-the-art digital camera and digital zoom, and is designed for high magnification video and micro-multisensing metrology. The digital zoom offers multiple magnifications, and a range of long working distance, precision fixed optical objectives are available. A granite base paired with a granite support column provide enhanced measurement stability, and 0.04 micron XY scales contribute to the attainment of high-accuracy measurements.

SmartScope Apex Micro is designed to measure tiny micro-manufactured parts that must adhere to extremely tight tolerances. For example, Apex Micro can provide full characterization of micro-electronic parts, EDM produced parts and precision medical device parts.

SmartScope Apex Micro is multisensor-ready for added versatility. Laser or the Rainbow Probe scanning white light sensor perform non-contact surface contouring, and a range of touch trigger probes are available for tactile measurement of hard-to-image features. The system may also be equipped with the Feather Probe micro-probe sensor that can acquire data points with only milligrams of probing pressure. When a High Precision Rotary air bearing rotary indexer with 1 arc-second accuracy, and a Feather Probe .005" stylus that can measure holes as small as .009" in diameter are coupled together, a fuel injector can be fully characterized.

MeasureMind 3D MultiSensor software provides full 3D measurement capabilities with programmable control of all sensors in any sequence, and complete data integration for detailed measurement verification of even complex/detailed parts. Optional software includes SmartFit 3D interactive 2D/3D fitting software, SmartProfile fitting software for GD&T environments and several others for SMP, 3D CAD import and custom report writing.

For more information contact:

Optical Gaging Products

850 Hudson Avenue

Rochester, NY 14621

800-647-4243 / 585-544-0400

info@ogpnet.com

www.ogpnet.com