Delcam CAM software designed to speed the programming and machining of complex parts will be shown.

Featured technology from Delcam will include the latest versions of the company's PowerMILL, FeatureCAM and PartMaker CAM systems. Visitors to the Delcam booth will see enhancements designed to help manufacturing companies, especially those in the oil and gas, aerospace and defense and automotive industries, to increase productivity, improve quality and reduce lead times.

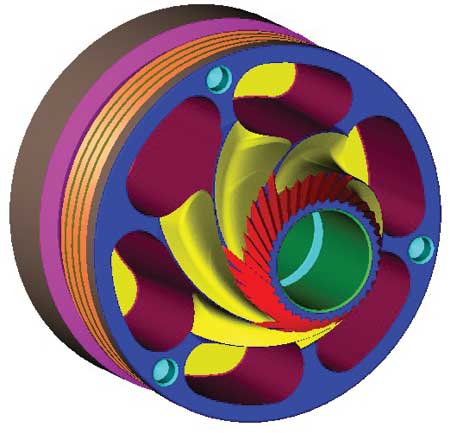

The new release of PowerMILL, Delcam's programming system for high-speed and 5-axis machining, includes improvements to the Vortex high-efficiency area-clearance strategy, expanded collision checking to also cover near misses, and more efficient raster finishing.

Vortex is designed to produce safe toolpaths with a much deeper cut by using a controlled engagement angle that maintains the optimum cutting conditions for the whole toolpath. As a result, the company reported that higher feedrates and material removal rates are possible, making the cutting time shorter by as much as 70%. In addition, cutting is undertaken at a more consistent volume removal rate and at a near constant feedrate, so extending tool life and protecting the machine.

"Two enhancements in PowerMILL 2015 will give even greater reductions in machining time with Vortex compared to conventional roughing," said a company spokesperson. "The first change allows toolpaths to approach the part from outside the stock at the cutting height for open pockets or in areas where earlier cuts have made this possible.

The second change allows an increased feedrate to be set for non-cutting moves. The extra time that can be saved depends on the shape of the part, but an additional saving of around 20% should be expected above the earlier releases of Vortex."

An increased range of strategies has been added to FeatureCAM to provide more efficient toolpaths that give greater productivity on a wider range of machinery, including mill-turn machines, 5-axis mills and wire EDM equipment. FeatureCAM 2015 includes a range of enhancements in 3-axis milling, 2-axis and 5-axis drilling, turning and turn-mill, and wire EDM to make the software more powerful and easier to use.

FeatureCAM 2015 also allows easier programming of families of parts. Working with the part library, the software matches the names of features within the part library with user-created curves relating to those features. This is designed to make the programming of subsequent parts in the family easier and faster.

Major highlights of PartMaker 2015, according to the company, include improved support for today's latest breed of multitasking machine tools, such as vertical mill-turns, more powerful milling and turning functionality, and a unique approach to post processing for multi-axis turn-mill centers and Swiss-type lathes, among other productivity enhancements.

PartMaker 2015 also incorporates a new approach to post-processing for multitasking machine tools. This approach includes a variety of improvements to the software's post-processing technology, together with new software functionality, to guide users on how to take best advantage of the unique capabilities of their specific multitasking machine tools.

For more information contact:

Delcam

877-335-2261

marketing@delcam.com

www.delcam.com

HOUSTEX 2015 Booth 1141