SVIA North American headquarters in Houston, TX

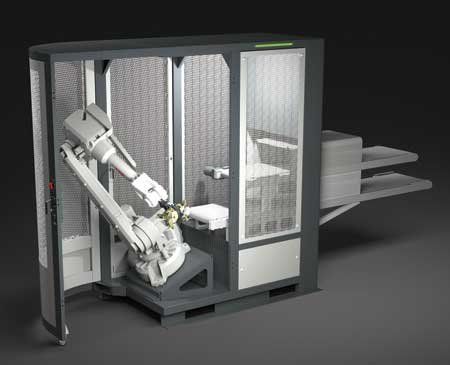

MT5 shown with side open

SVIA, an automation integrator founded in 1998 by Ari Kesti in Jönköping, Sweden, has opened a new North American headquarters where it has on display its latest product, the MT5. The new headquarters is located at 7210 Empire Central Drive, Houston, TX 77040 and is led by President Gary Frick.

SVIA's MT5 is compact and flexible and used for machine tending automation. The MT5 can feed two machines simultaneously or one machine and a number of additional process steps, such as deburring, cleaning and blow box, etc. SVIA works with customers to help customize the MT5 to fit their specific needs. The machine tending cell is available with conveyor belts or drawers, and can be equipped with an additional camera for super-precision.

SVIA develops complete and standardized robot cells with a flexible vision system for robot guidance. This provides flexibility for customers who favor shorter runs and smaller volumes. Today, there are 800 SVIA robotic cells in the European market.

SVIA recognized the potential in the U.S. market for its standard automation cells and vision system when one of its customers asked SVIA to help them automate a plant in Texas, similar to their plant in Sweden. SVIA team members from Sweden traveled to Texas and installed a standard turn-key solution, called FeedLine. Since then, SVIA has installed a second FeedLine cell to that customer.

Gary Frick, SVIA's U.S. President, has 17 years of experience in manufacturing and has worked in several states leading machine tool distribution companies. The North American team will be hosting learning events and also offering PickMT programming classes at its 22,000 sq. ft. Houston headquarters. "We have already sold 14 automated cells in Texas and Arkansas," said Frick.

"We have the capability to help customers with complete turn-key automated solutions, including installation, training, service and support," continued Frick. "SVIA always takes care of its customers. It is our goal to become a long-term automation partner that our customers can count on."

For more information contact:

Gary Frick, President

SVIA Industrial Automation

7210 Empire Central Drive

Houston, TX 77040

832-795-2070

www.svia.com