Coating for Roughing Steel and Hardened Alloys

November 1, 2015

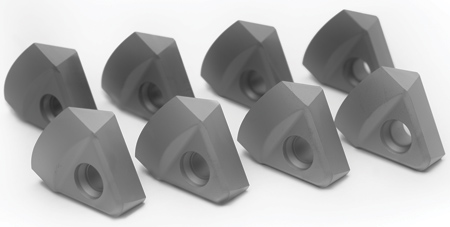

Ti-Coating's Alox SN2 PVD coating for roughing steel and hardened alloys, including castings

Ti-Coating announced its PVD coating Alox SN2 for indexable and solid carbide tooling. "The TiAlN-based coating provides excellent machining characteristics and extends tool life for a variety of applications including turning, threading and milling. The tough characteristics of Alox SN2 make it a capable choice for roughing steel and hardened alloys, including castings. The supernitride coating also provides high oxidation resistance," said a company spokesperson.

"For roughing applications, the addition of Alox SN2 gives customers a coating that holds up really well to the demands of heavy cuts in a range of materials that even includes hardened alloys, which can be very difficult to machine," said Keith Metzinger, Sales Manager for Ti-Coating.

For more information contact:

Ti-Coating, Inc.

50500 Corporate Drive

Utica, MI 48315

586-726-1431

www.ticoating.com

< back