Heavy Duty Machining of up to 600 Kg Workpiece Weight

January 1, 2020

DMG MORI's CLX 750 for workpieces of up to 600 kg with 8.9 sq. m. footprint.

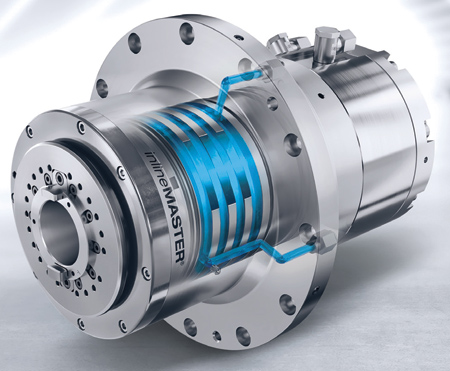

inlineMASTER spindle

DMG MORI has added to the CLX series with the CLX 750. Designed for workpieces up to 600 kg and a turning length of 1,290 mm, the universal turning center is particularly suited to the machining of large shafts. With DMG MORI technology cycles, the IoTconnector as standard and modern 3D control technology, the CLX 750 is ready for any forward-looking production. Customer-specific automation solutions complete the range of equipment.

Up to 1,290 mm turning length and a maximum turning diameter of 700 mm, or 640 mm in the version with the Y-axis, make the CLX 750 a versatile turning center in a wide range of industries. In the production of shafts, an optional steady rest supports turning operations up to a diameter of 430 mm. A Y-axis traverse distance of ± 80 mm is available for the eccentric machining of complex workpieces, while a sub spindle enables 6-sided complete machining. On spindle side, the CLX 750 offers 2,000 Nm torque and 46 kW power. DMG MORI uses an inlineMASTER spindle.

Modern 3D control technology from SIEMENS or FANUC is available, while exclusive DMG MORI technology cycles like alternating rotational speed, the Easy Tool Monitor 2.0 or the Multi-Threading Cycle enable easy and efficient machining. The IoTconnector is part of the standard equipment of all CLX machines. It enables digital networking of the machines, provides high protection by means of integrated firewall and enables pioneering service solutions with SERVICEcamera and NETservice.

For increased productivity, the CLX 750 can be paired with customized automation solutions from DMG MORI.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

www.us.dmgmori.com

< back