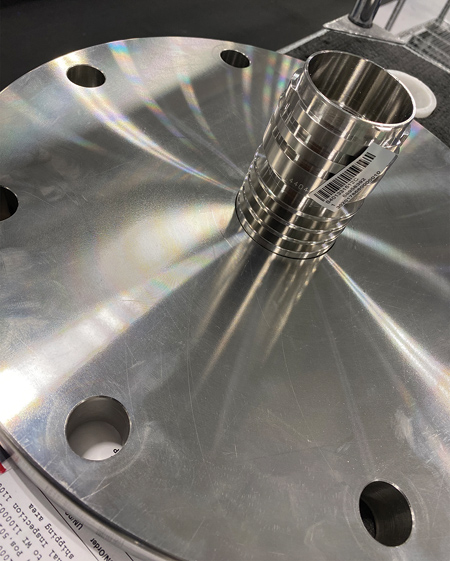

High precision adaptor manufactured by Endress+Hauser using a Hainbuch SPANNTOP workholding system.

When it comes to precision, there is no room for compromise at Endress+Hauser (E+H). The adaptors manufactured at the Greenwood, IN, plant are customer specific and dependent on the application for which the device is intended. They are critical to safety in many applications.

According to Leo Brosnan, Manufacturing Engineer-Mechanical & Fabrication, "As the leader in the Level + Pressure Instrumentation Industry, world-class safety, quality and delivery requirements call for world-class processes in workholding, tooling and equipment. As a result, process automation is key to our manufacturing strategy."

The primary component linking advanced level monitoring instrumentation with the customer's large-tank connection is machined from 316L stainless. The turning process requires dry (without coolant) machining and requires two tool positions on a single diameter part. To ensure accuracy, E+H opted for the Hainbuch SPANNTOP quick-change workholding system.

Richard Tillberry, Hainbuch Regional Sales Manager, explained: "Based on the workpiece sizes, E+H opted for a 65 mm SPANNTOP nova combi deadlength to fit an A2-6 spindle nose. The overall length is 135 mm, the chuck front diameter is 160 mm and the outer diameter is 165 mm. The SPANNTOP line, which is the original quick-change collet chuck, is available in seven sizes ranging from 32 mm to 125 mm. Four of the versions can be equipped with the MANDO Adapt mandrel T812 for I.D. clamping. Like all Hainbuch power chucks, the SPANNTOP line offers high holding power, parallel clamping with high accuracy, easy set-up and minimal inertia loss as compared to 3-jaw chucks."

Leo Brosnan recalled, "Ten years back, I bolted a Hainbuch quick-change chuck on a low-cost machine-a CNC gang style lathe. The chuck made a relatively inexpensive turning center world-class."

Brosnan continued, "The chuck was secured to the A-2 6 spindle nose, and the total indicator runout (TIR) initially was .0002 inches. Amazingly, I did not have to do more than tighten the face bolts to get this accuracy. After 10 years of running a dry machining process, the same chuck checks .0003 inches TIR with zero downtime on both the chuck and the machine."

Key to the continued accuracy and long life of the equipment is the commitment to ongoing maintenance. "We do recommend annual and daily maintenance on the machine, and we have worn out several collets over the years," said Brosnan. Some may wonder why we chose a quick-change collet chuck on a single diameter part with no need to change the machine over to another part. The answer is that the Hainbuch quick-change chuck allows us to perform fast and easy maintenance, which is critical to both continued accuracy and extended chuck/machine life."

Brosnan concluded: "The ability to upgrade a lower cost machine to our high accuracy standards has resulted in dual benefits: parts that meet rigid quality demands and significant economic benefits. I would not be afraid to put this same chuck on a new machine of any brand."

Tillberry commented, "An increasing number of our customers are discovering the advantages of equipping both low-cost and older legacy machines with Hainbuch workholding systems. The repeatability, clamping strength and versatility make it possible to machine the latest generation of complex parts with confidence while at the same time avoiding the expense involved in the purchase of a new or more costly machine.

"In a number of instances, customers who have started with one Hainbuch chuck have gone on to retrofit their entire shop with our products. The wide choice of sizes within the Hainbuch line accommodates a full range of parts, and the user-friendly quick-change design makes for more efficient use of manpower-another important consideration."

For more information contact:

Endress+Hauser

2350 Endress Place

Greenwood, IN 46143

888-ENDRESS

info.us.sc@endress.com

www.us.endress.com

HAINBUCH America

W129 N10980 Washington Dr.

Germantown, WI 53022

800-281-5734 / 414-358-9550

sales@hainbuchamerica.com

www.hainbuchamerica.com