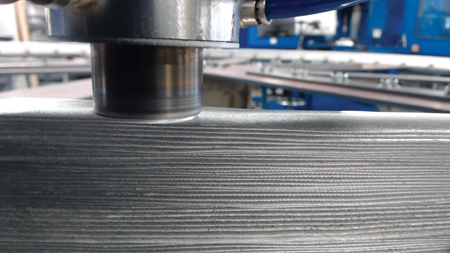

Close up of deposition of recent large 10' diameter cylinder printing

MELD Manufacturing Corporation, developer and provider of MELD 3D printing machines for metal, has released data confirming that the process produces titanium meeting the ASTM and AMS standards for forged material, as printed.

The data was generated through a program with the National Center for Manufacturing Sciences (NCMS), Army Research Laboratory (ARL) and the Advanced Manufacturing, Materials and Processes (AMMP) program using Ti-6Al-4V (Ti64) material, also known as ASTM Grade 5, for the testing.

The data highlights that the as-printed material exceeds the minimum requirements for yield strength, ultimate tensile strength and elongation as specified in ASTM B265, ASTM B381 and AMS 4911 in all axes, including through the print layers. ASTM B265 is the ASTM standard specification for Titanium and Titanium Alloy Strip, Sheet and Plate. ASTM B381 is the ASTM standard specification for Titanium and Titanium Alloy Forgings. AMS 4911 is the AMS specification for Titanium Alloy, Sheet, Strip and Plate, 6Al - 4V, Annealed.

Chemistry analysis shows that MELD Ti6-4 is consistent with the feedstock material and conforming to the requirements of ASTM B265, ASTM B381 and AMS 4911.

"MELD Ti6-4 has been third-party (NADCAP accredited) verified to produce fully dense, isotropic material that exceeds the minimum mechanical performance requirements defined in ASTM B265, ASTM B381 and AMS 4911 for Grade 5 Titanium Alloy (6% aluminum 4% vanadium), as printed. Test results demonstrate with statistical significance (e.g., MMPDS S-Basis) that Ti6-4 printed using the MELD process satisfies the requirements of wrought Ti64," said Process Engineer Ryan Henderson. "Optical microscopy and SEM investigations produced images that revealed clean, defect-free material. The MELD deposited Ti6-4 is monolithic, as individual layers are not visible during evaluations."

Ti6-4 is a desirable alloy because it has a high strength to weight ratio and a favorable balance of properties. Its high cost prevents use in components that would require a large amount of material to be machined away. MELD enables use of this material by printing only what is needed.

"No other additive process can deliver Ti6-4 at scale with isotropic properties consistent with forged material," stated Chase Cox, Director of Technology.

The company delivers machines and services using its patented MELD process for creating and repairing metal components using off the shelf material in open air. MELD is unique because it does not melt the metal and prints fully dense parts.

For more information contact:

MELD Manufacturing

200 Technology Drive

Christiansburg, VA 24073

540-951-3980

websales@meldmanufacturing.com

www.meldmanufacturing.com