The NHX 4000 3rd Generation features 5.6 sec. chip-to-chip time, 0.5 sec. tool change time.

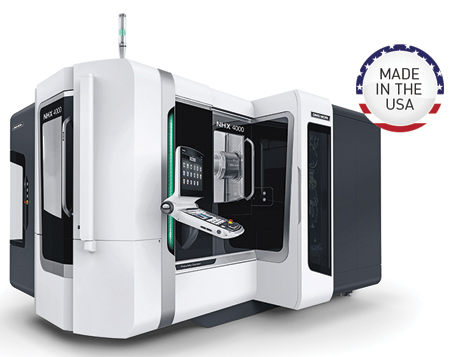

NHX 4000 3rd Generation, built in Davis, CA, offers flexible and economic production due to its extensive range of automation options.

DMG MORI offers the NHX 4000 3rd Generation horizontal machining center (HMC) for horizontal machining of complex workpieces. Built in Davis, CA, it is equipped to provide flexible and economic production due to its range of automation options.

The NHX series features sturdy construction for stable and high-quality machining. The X- and Z-axis guides are arranged to maximize rigidity of the bed, column and spindle. DMG MORI has increased the stability of the NHX 4000 3rd Generation even further, primarily with dynamics in mind. Acceleration rates of 1.2 g in all axes and 60 m/min rapid traverses contribute to high overall performance.

The speedMASTER motor spindle provides high chip removal rates. It offers a speed of 20,000 RPM, a power rating of 37 kW and a maximum torque of 163 ft-lbs.

Hydraulic fixtures mean the NHX 4000 3rd Generation is easy to automate. It is equipped with a pallet changer when it leaves the factory, which moves the workpieces weighing anything up to 882 lbs. to the work area after setting up parallel to machining. Users achieve a higher level of productivity due to intelligent automation solutions. These range from a pallet handling system with up to 21 stations for a stand-alone machine and 99 pallets in a linear pallet pool for several machines and on to include direct workpiece handling using a robotic system. The product range is designed for both experienced users and those entering automated production for the first time.

With 60 tool pockets, the NHX 4000 3rd Generation offers a large magazine to meet the high productivity demands. The cooling system includes a coolant tank with a filter unit and spindle cooling. Direct path measuring systems from MAGNESCALE, laser measuring probes and a sensor package that includes machine protection control round off the available options. The FANUC NC control and CELOS operator interface provide an integral digital process that encompasses job preparation and monitoring right through to documentation.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI (364-6674)

www.us.dmgmori.com