The new, easy-to-operate machine control from Schwarze-Robitec clocks the individual working steps synchronously for time-optimized production.

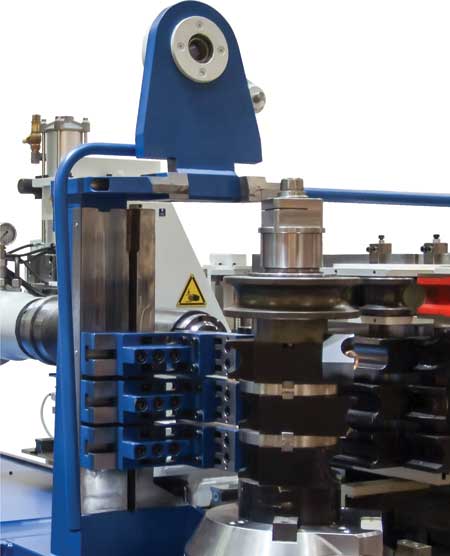

The rapid clamping system is designed to enable fast and uncomplicated tool change.

Schwarze-Robitec has developed a series of sustainable and labor saving products for the tube processing industry.

The integrated residual length optimization for tube bending machines, designed for automobile industry suppliers, is engineered to reduce residual tube lengths to a minimum for increased material savings. "Customer trials have shown that the material input, depending on the tube system, could be reduced by up to 20%," said a company spokesperson.

Another product from Schwarze-Robitec is the Terminal-End-Bender, which is used for the manufacture of tube systems in power plant construction. "With this additional bending machine, bends in both directions are conducted subsequently at the rear end of the produced tube coil without having to interrupt the fully automatic manufacturing process," said the spokesperson. "The Terminal-End-Bender helps to save time. A further new development is the rapid clamping system for bending tools in series and mass production, which enables fast and easy tool change. Unproductive set-up times are significantly reduced."

At the booth, the company will also feature the CNC 60 E TB MR bending machine equipped with multi-tools. It allows production of different radii as well as bend-in-bend systems. "It is particularly suitable for the manufacture of exhaust pipes with a bending radius of 1 x D without straight intermediate lengths between two bends," said the spokesperson. "Due to the multi-bend tools, set-up times are reduced to a minimum. Further cost savings can be achieved with the separating system integrated into the bending system. Here, several individual tubes are coupled to one bending program and are separated after bending with maximum speed by means of the separator. Since clamping and support lengths are not required, there is considerably less material loss and scrap."

Time savings was a central focus for Schwarze-Robitec when developing the new machine control. "The control software brought onto the market in 2014 reduces non-productive times to a minimum, as the original sequence of the bending process is broken up and the individual steps are arranged synchronously," said the spokesperson. "The integrated diagnostics and maintenance tool guides the operator through all setting and optimization steps and checks all data reliably for validity. If the machine operator forgets to define a parameter, the tool will remind him of it. Equipped with a touchscreen, it can be operated intuitively, which also contributes towards making work easier."

"The use of this control for tube bending machines leads to a productivity increase of up to 25%," said Bert Zorn, Managing Director of Schwarze-Robitec. "The uncomplicated operating concept makes it possible to familiarize new employees in only a few hours."

For more information contact:

Schwarze-Robitec GmbH

Olpener Str. 460-474

51109 Cologne

Germany

+49 (221) 89 00 8-0

sales@schwarze-robitec.com

www.schwarze-robitec.com

FABTECH Booth B4625

Trilogy Machinery, Inc.

P.O. Box 70

Belcamp, MD 21107

410-272-3600

sales@trilogymachinery.com

www.trilogymachinery.com