Horizontal Turning Lathe for Rough and Fine Turning Needs

October 1, 2014

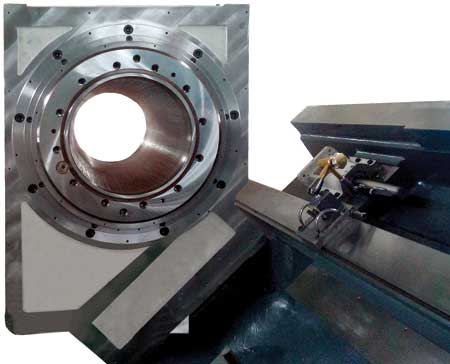

The FBL-520D features a 15" through hole, easy access and single-piece casting.

Chevalier's FBL-520D heavy-duty horizontal turning lathe is designed for machining heavy parts and large pipe threading, such as those found in the energy and aerospace industries.

"The series features highly accurate machining that can handle rough and fine turning operations," said a company spokesperson. "The gear box provides enough horsepower for heavy-duty turning. With live tooling capability, this series can save time by milling and turning a part in the same set-up."

The series structure features a 45° slant-bed design comprised of single-piece Meehanite cast iron with a wide-span, ribbed box structure. For stability and support, the machine provides box guide ways that are 5.1" wide by 3.1" thick. A 60 HP spindle motor, which features a two-stage gearbox and generates 9,000 Nm of torque, is designed to satisfy most cutting conditions of large diameter workpieces or tough material applications. The 12-station turret is 200 mm thick for deep hole boring and rough turning. The 15" through hole can be used for pipe yard threading and meets API thread standards. Maximum swing diameter is 40" and cutting diameter is 37". Dual-chuck, easy-access design provides convenient loading and unloading of longer parts.

The standard programmable tailstock has a built-in MT-6 rotary quill that, according to the company, provides better parts weight support than a normal live-center type of quill. Standard link-type chip conveyor is also a standard accessory. An optional BMT85 power tool turret is available for milling the part with one set-up.

"The FANUC 0i-TD control with FANUC digital servo drive and motor are standard features with the FBL-520D," said Chevalier National Sales Manager Herbert Hou. "They represent a substantial cost savings and value for our customers."

For more information contact:

Herbert Hou

Chevalier Machinery Inc.

9925 Tabor Place

Santa Fe Springs, CA 90670

562-903-1929

info@chevalierusa.com

www.chevalierusa.com

< back