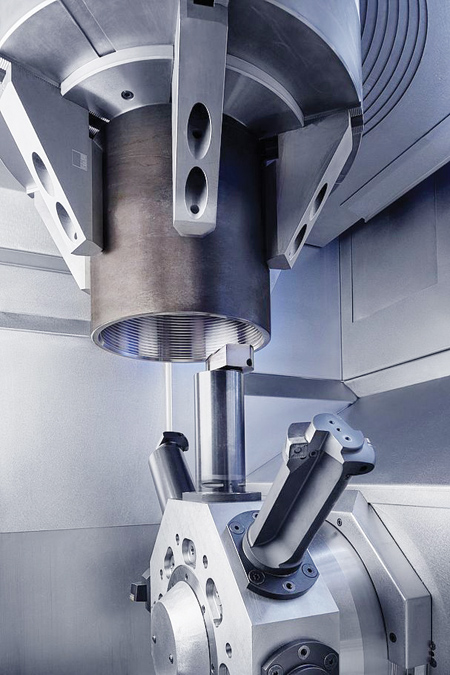

The VLC 500 CM covers the production of couplings for the premium segment.

The VLC 500 CM vertical coupling machine for the production of 2-3/8" to 13-3/8" couplings.

EMAG's patented TIS optical measuring system allows for the non-contact measurement of all types of pipe and coupling threads.

According to the 2018 energy study of the German Federal Institute for Geosciences and Natural Resources (BGR), oil, with a share of 30.5% of the world's primary energy consumption, remains the most important source of energy.

"However, global trade restrictions complicate the extraction and importation of this `black gold,'" said an EMAG spokesperson. "China, for example, is required to extract its own oil in order to meet its domestic demand. China's hunger for energy pushes the country to drill for oil at record depths-8,875 m (29,118 ft) below ground, which is lower than Mount Everest is tall."

"The continued push to drill deeper set high requirements on the quality and type of premium grade threads found on conveying and ascending pipes, and the corresponding couplings," continued the spokesperson. "The need for a measuring system is also critical in order to minimize errors."

To meet this demand, EMAG has created a patented system that measures the thread connections of pipes and couplings with no contact, and is performed completely autonomously.

Non-Contact Pipe and Coupling Thread Inspection System

"Manually measuring thread and sealing geometries after cutting threads on pipe ends and couplings is a time-consuming and labor-intensive process," said the spokesperson. "However, the measuring process is essential due to the growing requirements on premium threads. Using the patented method developed by EMAG Leipzig, for the first time, the geometries of pipe and coupling threads can now be measured without contact. The contactless optical measuring system does not require any labor and can be used autonomously or integrated into a complete process chain."

"The advantages of the Thread Inspection System (TIS) are obvious: the potential savings resulting from its unmanned operation alone are tremendous," continued the spokesperson. "For example, consider a coupling machine with an annual production capacity of about 1.3 million couplings; savings can stretch beyond six figures, and can be achieved quickly."

The new system is also designed to provide constant measurement accuracy with the shortest possible measuring times. Once the measurements are taken, feedback is directed right back to the machine's CNC control unit, allowing tool corrections to be made automatically and immediately during the machining process.

This error-minimizing system measures all thread types known today (API and premium threads). This allows for the complete elimination of the manual measurement process.

Another advantage provided by this method is the detection of insert wear, allowing optimal insert changes to be performed and reducing tool costs. This also avoids undesirable downtimes due to worn tools.

Process Optimization Through Digital Twin

EMAG has been supplying flexible machine concepts and comprehensive systems for the manufacturing of pipe ends, couplings, tool joints and other oilfield components for decades. "Complete cells including machines, robots, measuring systems and marking units are all directly supplied by EMAG. By acquiring all of the systems from a single source, EMAG can permanently optimize your process chains-not only for thread cutting, but also upstream and downstream processes," said the spokesperson. "EMAG uses the most innovative development methods, such as the digital twins, so that the manufacturing process can be simulated and then adjusted. A machine system that meets all of the demands for the production of couplings has been developed based on this methodology: the VLC 500 CM."

VLC 500 CM Vertical Coupling Machine

With its high range of diameters from 2-3/8" to 13-3/8" and a maximum coupling length of 400 mm (16"), the VLC 500 CM covers a large range in coupling production and can be implemented with a high amount of flexibility. The VLC 500 CM also offers high productivity and powerful drives. With its modular structure, the machine can be adapted to perform a variety of machining tasks. The pick-up process is used to automatically load and unload the machine, and the dynamic axes further provide minimal non-productive times.

For more information contact:

EMAG L.L.C.

38800 Grand River Ave.

Farmington Hills, MI 48335

248-996-4703

www.emag.com