Tsunami Medical deploys a fleet of four Concept Laser Mlab systems from GE Additive to drive innovation, speed and productivity gains in the spinal implant sector.

To further scale production, in 2020 the company acquired two additional Concept Laser Mlab systems-doubling its fleet size to four machines.

Since its foundation over 20 years ago in Italy's biomedical valley near Modena, Tsunami Medical has continued to evolve and grow its business in response to the market dynamics of the ever-changing global medical implants sector.

"At the heart of the company's evolution is a robust, innovation strategy that embraces and integrates new technologies such as additive manufacturing (AM). This allows it to remain at the forefront of the design, development and manufacture of medical devices for spinal surgery and invasive procedures," said a spokesperson.

After quickly establishing expertise in the field of biopsy and vertebroplasty, already in 2010, Tsunami Medical founder and General Manager Stefano Caselli and his team had started to explore how metal additive technologies could be applied to spinal cages and implants.

The purchase of its first two DMLM machines in 2015 marked a significant major milestone in the company's additive journey. Today Tsunami Medical remains focused on the spinal sector and to date has additively manufactured more than 50,000 pieces for its global customers.

Fast-Paced Innovation in the Spinal Device Sector

Innovation in spinal cage implants has come a long way in a relatively short period in time. This is in part due to companies like Tsunami Medical, who work hand in hand with forward-thinking orthopedic, neurosurgeons and other medical professionals to integrate metal additive into their work.

"Compared to early PEEK-based implants, metal AM now not only makes it possible to calibrate the mechanical properties, elastic modulus and rigidity of a device; it also allows device designers the freedom to create open structures in a quality that is close to replicating the porous structures of trabecular bone," said the spokesperson.

Another advantage of additively manufactured structures is that they can be incorporated into the shape of the implant and produced in one production step-without the need for additional coating. This allows for the design of porous structures with customized conformations of pores, thickness and overall porosity.

"That collaboration and shared learning with medical and healthcare professionals around the world is invaluable. Their ideas and continued enthusiasm for metal additive energizes us and helps to influence and shape our innovation strategy going forward," said Caselli, himself a biomedical engineer.

DMLM Drives Innovation and Productivity Gains

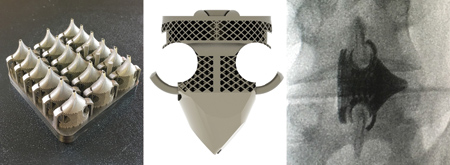

Innovation at Tsunami Medical comes in various shapes and forms, but they are typically small and incredibly complex. The company's latest innovation breakthrough-the Giglio Interspinal Fusion System-focuses on developing implants that are almost ready for use, straight from a metal AM machine.

The system is intended for lumbar diseases with an indicated segmental requirement. This covers a wide range of medical conditions, such as degenerative disc diseases, vertebral instability, review procedures for post-discectomy syndrome, pseudoarthrosis, a lack of spinal fusion or degenerative spinal fusion and adult deformities.

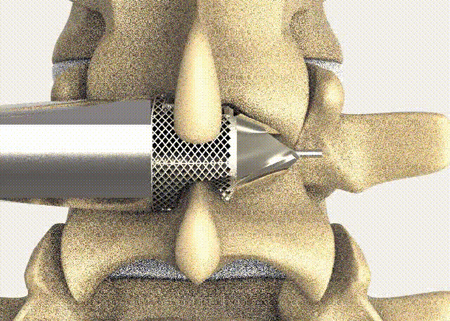

Giglio consists of an interspinal spacer device and the necessary tools for its positioning and fixing within a minimally invasive operation. Five mobile, articulated pieces allow for the extraction of the fins for anchorage to the vertebrae.

The surgical operation is performed by making an incision for the passage of the device. This is correctly positioned using a guide wire that is stretched from the insertion point. Once the device has been positioned, it is tightened by a special tool, which is then removed, together with the guide wire.

Here, Tsunami has been able to take advantage of GE Additive's DMLM technology in a number of innovative ways. DMLM offers the ability to create precise geometries, including gears and mechanical moving parts on a very small scale with no assembly needed.

"DMLM helps us achieve the accuracy, complexity and functional integration we are striving for. It also delivers a great surface quality than reduces or sometimes eliminates the need for typical post-processing, which in turn drives productivity gains," said Caselli. "The implant comes out of the machine with an optimized 20-unit printing cycle, without the need for support structures. It is already fully assembled and except for final polishing requires no post-processing. No other machine today would have been able to give us this kind of performance."

As demand grows from its international customer base, Caselli plans to scale the business further.

For more information contact:

GE Additive

www.ge.com/additive