Accurate Force Measurement in Low Measuring Ranges

March 1, 2021

The new generation of SlimLine sensors features improved linearity in low measuring ranges.

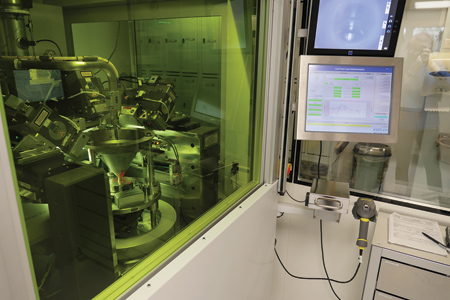

Kistler is producing the entire SlimLine C series in a clean room.

At the heart of every piezoelectric sensor is a quartz crystal.

"In smart manufacturing, measurement tasks are more challenging and call for increasingly advanced technologies. With the latest generation of SlimLine sensors, Kistler has optimized its series of force sensors," said a company spokesperson. "The SlimLine ring force transducers feature significantly improved linearity in low measuring ranges. This makes the application of these small force transducers even more flexible."

The individual SlimLine sensors of the C series replace the predecessor models and offer additional benefits for operators. The design has been enhanced by a number of details, making the sensors in the new series more sensitive. The new design also improves linearity, especially in low measuring ranges.

Kistler is producing the revised sensor series in a clean room. The components are welded under nominal load conditions, reducing the recommended preload from 50% to 20% of the nominal range. This facilitates easy installation and often saves space. The compact design is particularly relevant for the measurement of press-in or punching forces as well as large forces in force shunts, for monitoring progression tools and for small dynamometers. Due to their high rigidity, SlimLine sensors are suited for monitoring dynamic forces-measurements over several minutes are now possible.

"Optimizations in production also lead to significantly improved throughput, which increases availability," said a company spokesperson. "Additionally, high material quality is guaranteed due to complete traceability. The parameter stiffness, natural frequencies and temperature sensitivity coefficients were added to the data sheet to provide measurement engineers with additional information for challenging measurement tasks. Despite these upgrades, the new sensors are reverse compatible with their respective predecessors."

For more information contact:

Kistler Instrument Corp.

30280 Hudson Drive

Novi, MI 48377

248-668-6900

sales.us@kistler.com

www.kistler.com

< back